When defects are missed, turn to automated inspection

Critical defects are easily missed when inspecting manually. Tiredness, distractions, and boredom are no match for high-speed production lines. Detailed examination, potentially using templates, images, or measurements, is a time-consuming process, and unsuitable for use in a production line where parts are made at over 12 per minute. AOI machines, or automated optical inspection machines are needed to maintain quality levels.

In this example, battery packs manufactured on an automated line require the correct placement of two rubber stickers. These must be completely undamaged and correctly placed within a predetermined positional tolerance. Also, the surface finish of the stickers is subtly variable. The batteries are placed on a conveyor belt at 12 per minute and need inspection.

An AOI machine is the only solution

The Inspekto S70 autonomous machine vision system is an out-of-the-box automated optical inspection solution, that can be set up in 30 minutes, learns like a human and inspects like a machine. It combines automated machine precision with the adaptability of human sight to the production line. Its cutting-edge AI technology is trained from “good” components, not predefined defects, making it incredibly easy to set up. Flaws are identified, positions checked, and missing components flagged, while automatically ignoring non-critical variations like serial numbers.

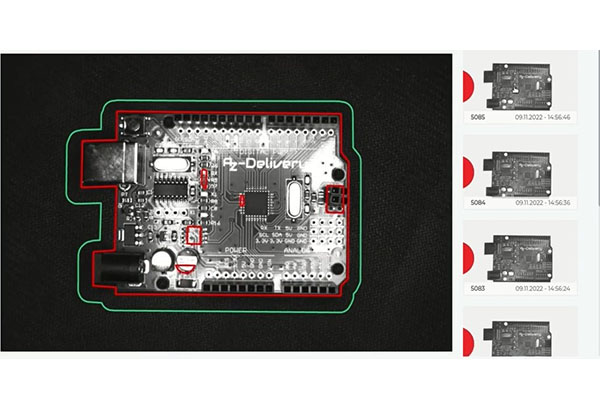

The S70 is built for speed and efficiency, it is tolerant of orientation and positioning and can scan components placed in the camera’s field of view, and on a conveyor belt, at rates exceeding 40ppm. These defects are identified in red on the displayed or recorded image to facilitate rework. This powerful blend of speed, accuracy, and autonomy transforms your quality control process, ensuring you catch what others miss.

The S70

The S70 can be used on many materials/components, including Electrical Components, Metal, PCBs, plastic, and rubber. This capability makes it an ideal solution for products such as injection moulded components where it can identify sink marks, pores, dents and flashing, electrical connectors-presence/missing/position, soldering on PCB’s, integrity & milling swarf in metal components, position and presence of labels, verification of coatings and O ring placement or missing.