Precision and performance: a new standard for turbine blade inspection

In the safety critical world of aerospace and energy, the performance and safety of turbine blades is critical. Bruker Alicona have partnered with industry leaders to develop optical inspection tools, to provide rapid, non-contact measurement solutions delivering comprehensive 3D analysis using focus variation.

Using a single measurement sensor, with a single, high-precision optical sensor either on a measurement system, or on a cobot system our Alicona systems are able to:

- Validate critical components: Confidently inspect fir tree geometry and surface finish.

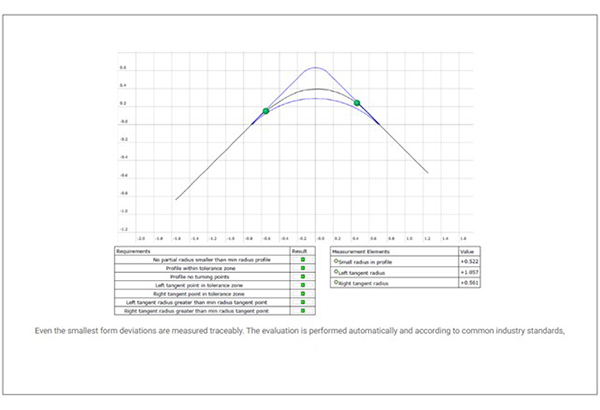

- Perfect the aerofoil: Measure leading and trailing edge radii, deviation of form, and profile twists with micron-level precision.

- Assess surface integrity: Measure profile (Ra) and areal roughness(Sa) to measure surface finish of material and coatings.

- Measure the smallest flaws: Quickly measure surface defects that could compromise performance.

- Master the intricacies of cooling hole geometry: Accurately measure the form, position, and diameter of these vital features to ensure optimal thermal management.

A future-proof turbine blade inspection solution

The Alicona G6 with Real 3D rotation unit is ideal for the rapid measurement of the geometry and surface roughness of high value components.

Recent developments include

- Vertical Focus Probing – the optical probing and measurement of holes (such as cooling holes) and vertical flanks

- SmartFlash – designed to ensure high resolution measurement of smooth, reflective and highly polished surfaces

- 5 axes metrology – the high precision rotation unit allows measurement of complex geometries, enabling capture of GD&T data and roughness parameters on an entire object

The G6 is in regular use at several European facilities measuring turbine blades both when manufactured and when removed for evaluation at end of life.

The Alicona G6 with Real 3D rotation unit

The G6 being the latest in a long line of products from Alicona, uses focus variation coupled with a sample mount capable of positioning the sample in 3 dimensions. It will measure to sub micron accuracy, combining the functionality of a roughness measuring system with a coordinate measuring machine.