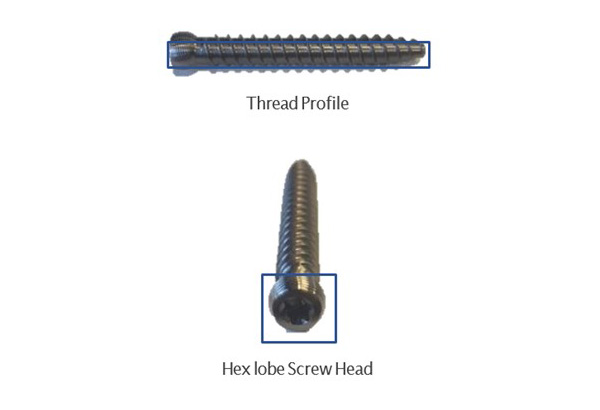

Inspecting precision screws for automotive, engineering and medical device industries

The dimensional and finish checking processes for screws vary depending on their use. Falling into two main groups, ordinary and high-precision screws. Ordinary screws, such as wood screws, are produced in very high volumes and precise tolerances are not critical. The focus of quality control is on high-speed, automated checks to ensure basic functionality and form. Vision Systems can provide additional detailed checks.

High-precision screws though, used in applications like automotive, precision engineering and medical devices, have more stringent dimensional and surface finish specifications. The inspection process is far more rigorous, often involving 100% inspection and advanced metrology.

Dimensional inspection of high-precision screws

3D optical metrology uses non-contact methods to capture a complete, high-resolution 3D model of the screw’s surface and form in a matter of seconds. They are used to measure complex features and ensure every dimension, including thread form and pitch diameter, meets the tight tolerances. They also allow measurement of surface finish.

Automated Optical Inspection (AOI): Advanced vision systems, like those from Kitov AI or Inspekto S70 use high-resolution optical system to create a precise 3D model of the screw. These systems can inspect 100% of the parts for accuracy, including minute details like thread runout and feature relationships and can also detect subtle surface defects like scratches, nicks, pits, or inconsistencies in plating. They are fast enough to be used in-line with production.

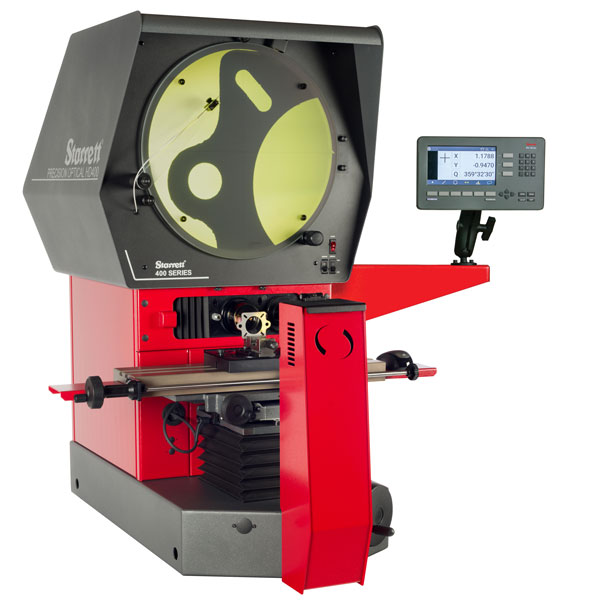

Optical Comparators/Profile Projectors: These systems work by projecting a silhouette of the screw on a screen which is compared against a detailed overlay providing accurate comparison of thread forms and radius.

Finish Checking: Surface finish can also be a critical feature and can be checked with 3D optical metrology or with a profilometer

Powerful AI tools can provide the solution. For example, the Inspekto autonomous machine vision system uses a camera and a powerful AI image processing system to spot defects whilst minimising false positives. It is tolerant of orientation and positioning and is capable of scanning components placed, in the camera’s field of view and on a conveyor belt at rates exceeding 40ppm. But not all applications are suitable for automated inspection, if you are unsure which is the best solution, please contact our application team for advice.

The S70

The S70 can be used on many materials/components including Electrical Components, Metal, PCB’s, plastic, and rubber. It provides an ideal solution for products such as injection moulded components where it can be used to identify sink marks, pores, dents and flashing, electrical connectors-presence/missing/position. Not only this, it can be used for soldering on pcb’s, integrity & milling swarf in metal components, position and presence of labels, verification of coatings and O ring placement or missing. A very comprehensive product.