3D scanner for car castings helps Poland’s oldest foundry

Metalpol, Poland’s oldest foundry, were faced with the challenge of how to improve quality control for precision castings used within the automotive industry among others. The sheer variation in their precision castings – from large components to small, complex 3D parts – made manual quality control nearly impossible. To solve this problem, they turned to modern technology: the eviXscan 3D scanner. This automated system captures every minute detail of a casting, ensuring flawless quality control. Moreover, the eviXscan allows the company to recreate parts for which no blueprints exist with reverse engineering. This integration of old-world craftsmanship with state-of-the-art 3D scanning technology has transformed Metalpol’s operations, making them faster, more efficient, and even more competitive aligning with the highest standards in the automotive industry.

Metalpol take advantage of the best 3D scanner for automotive castings

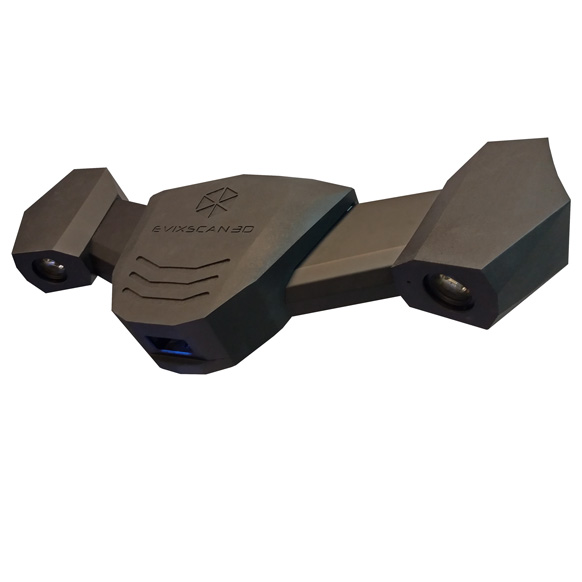

EviXscan recommended the use of an eviXscan 3D Pro+ scanner, seamlessly integrated with a 200KG turntable, facilitating swift and efficient scanning of large and heavy castings.

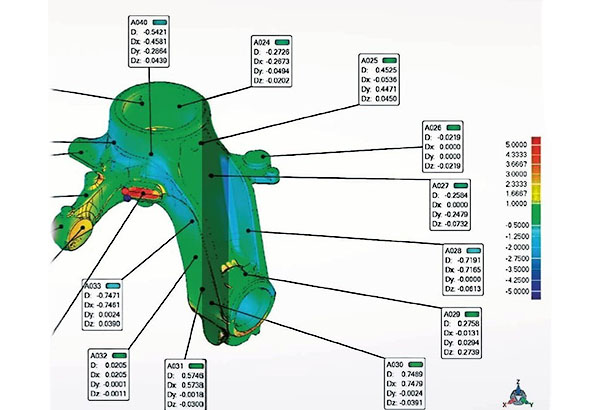

This advanced 3D scanning technology generates precise and detailed measurement data for the intricate castings manufactured at the foundry. The data obtained is compared against the customer-supplied CAD model, ensuring strict adherence to design specifications.

More advantage has been realised with prototype castings. The measurement data obtained serves as a valuable tool for collaboration with the data shared with the customer, allowing for thorough study and approval before initiating the full-scale production run. This approach not only ensures the alignment of the final product with customer expectations but also enhances transparency and collaboration in the manufacturing process. Also, in the case of no CAD data being available, the system can be used for reverse engineering of automotive castings where parts are available.

Looking to improve your quality control and reverse engineering capabilities within automotive manufacturing? Optimax, the UK’s exclusive supplier of eviXscan solutions, can help. Contact us today for a consultation and a demonstration of how this powerful 3D scanning technology can transform your manufacturing process.

EviXScan Quadro+

Built for the future, we recommend the 2 in 1, Quadro+ for 3D scanning technology that can even cater to customers without specific drawings for a particular component. A sample can be subjected to 3D scanning, from which a detailed CAD model is generated. This initial model undergoes refinement, leading to the creation of a prototype. Should the prototype meet the customer’s requirements, it serves as the green light to start commercial production. This is just one of the assets of the eviXscan, and a must for any business looking for a more streamlined approach.