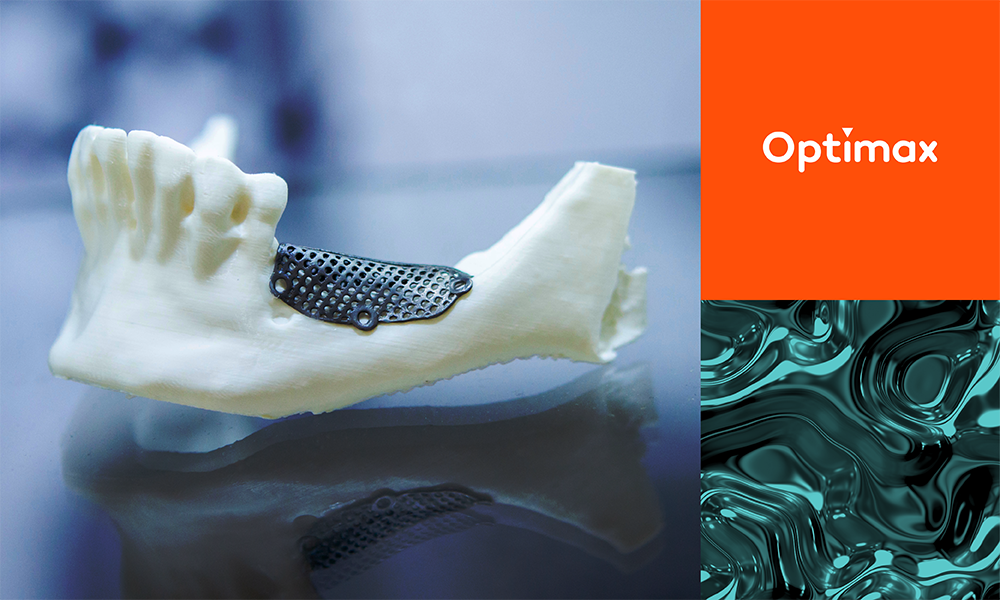

CNC machining is a widely used in manufacturing in the medical device industry, where precision is paramount. The intricate and critical nature of medical device components require a comprehensive inspection process to locate any imperfections or irregularities causing compromise the functionality or safety of the final product.

Complexities of medical device manufacturing

Medical components will have complex geometries, and common issues would include scratches, scuffs, tool marks, tolerance violations, misalignments, material defects, internal flaws, foreign particles, surface finish issues, and burr and edge quality.

A highly regulated manufacturing industry

As the medical device industry is highly regulated a robust inspection process is essential to detect these defects and ensure that the final medical devices adhere to stringent functional, safety, and regulatory standards. As such, inspection processes must not only identify defects but also document and trace them to comply with regulatory demands. As defects in medical devices can have serious implications, affecting patient safety and treatment outcomes this is safety critical.

Manual optical inspections are not sufficient on their own due to the limitations of human vision and operator fatigue. Advanced optical inspection systems, therefore, play a crucial role in the quality assurance process.

Systems that can capture high-resolution images and provide precise measurements are essential for evaluating complex components. The combination of optical systems and human expertise ensure a thorough inspection process aligning with regulatory standards and industry best practices.

For maximum effectiveness, inspection equipment must be user-friendly and require minimal operator training. For example, the EVO Cam II Digital Microscope is highly recommended for optical inspection and measurement. It offers up to 50x magnification, enabling the detection of minute surface imperfections such as scratches that might not be visible to the naked eye. The microscope’s exceptional HD image quality and high frame rate eliminate motion blur, ensuring that every detail is captured with precision.

Analyse defects in medical devices during manufacture

The use of advanced equipment, like the EVO Cam II, allows for a comprehensive analysis of defects as when imperfections are identified, they can be accurately measured and documented. This data is invaluable for root cause analysis, allowing manufacturers to trace issues back to specific stages in the production process. allowing manufacturers can implement targeted process improvements, reducing the likelihood of future issues and enhancing overall product quality.

In conclusion, thorough inspection processes in CNC machining are crucial for the medical device industry. They not only ensure that products meet high-quality standards but also contribute to regulatory compliance and patient safety. By leveraging advanced inspection technologies and combining them with skilled human oversight, manufacturers can produce safe, reliable, and effective medical devices. This meticulous approach ultimately benefits both healthcare providers and patients, reinforcing the importance of precision and quality in medical device manufacturing.