The year 2026 is almost here, which means it is time to ensure your manufacturing processes and inspection are equipped for the future. Optical metrology tools are one of the keys to achieving micron-level precision to maintain zero-defect quality in today’s complex production environments. It provides fast, non-contact measurement that dramatically improves inspection, quality control, and product development.

Optimax provides a wide range of optical metrology tools and here we show three simple ways to level up your quality assurance.

Level 1: Digital Clarity on the Benchtop with EVO Cam II

The EVO Cam II Digital Microscope is a useful upgrade from traditional stereo microscopes. This optical metrology instrument can be to bring high-definition inspection to every operator’s bench. Unlike traditional stereo microscopes it does not use eyepieces providing fast, comfortable ergonomic inspection and basic measurement.

Benefits

- Exceptional Images: Full HD video feed provides ultra-sharp images with up to 760x optical magnification and up to 9000x digital zoom to visualise even the smallest feature.

- Ease of Use: The EvoCam is a free-standing instrument and does not require a PC. It uses simple on-screen controls, up to ten presets are available allowing quick changes between tasks allowing users to operate it with minimal training.

- Depth of Field: Focus Stacking is a process that automatically combines images taken at different focal depths to create a single, fully focused image. This makes the system valuable for inspecting objects with uneven or complex surfaces.

- Simple Measurement: On-screen measurements such as point-to-point distance, Radius/Diameter, angles, and grid overlays for easy comparison against standards.

Applications

- Electronics: Inspection of solder joints, PCBs, and tiny components.

- Precision Engineering: Quality checking of small parts, to identify micro-cracks, burrs etc. and verifying surface details.

- Medical Devices: Non-contact inspection of small, intricate parts.

- General Rework: Providing a large field of view and long working distance for comfortable manipulation and assembly tasks under magnification.

Level 2: Automated 3-Axis Measurement with the Starrett AVR300 Vision System

If the EvoCam is not sufficient in terms of measurement and the need is for repeatable, high-accuracy dimensional measurements, the Starrett AVR300 CNC Vision Metrology System is your next big leap in optical metrology. With this system it is easy to automate complex 2D and 3D measurements and allows users to simply place an object on the stage and select the appropriate program for auto measuring.

Benefits

- Automated Precision: Using CNC (Computer Numerical Control) operation ensures accurate, precise, and repeatable results during repetitive measurement regimes without risk of operator error.

- Micron-Level Resolution: The use of high-resolution interchangeable telecentric or zoom optics provides an accuracy of up to 2µm.

- CAD Comparison: Automatic comparison to CAD files is provided by the MetLogix™ M3 software allowing for, instant verification of part conformance.

- Versatile Measurement: It measures a variety of 2D geometric elements (lines, circles, angles) and offers 3-axis measurement (X-Y-Z) capability. It is also compatible with an optional Renishaw touch probe for measuring complex 3D forms.

Applications

- Quality Assurance: Repetitive, high-volume measurement routines for consistent part inspection.

- Precision Machined Parts: Accurate non-contact measurement of critical dimensions on turned, moulded, or CNC-machined components.

- Plastic Mouldings & Casting: Quick verification of the geometry and dimensions of features.

- Aerospace & Automotive: Ensuring part conformance to meet strict sector requirements.

Level 3: AI-Driven Robotic Inspection with KITOV.AI

TheKitov.AIis a robotic visual inspection tool that will eliminate human subjectivity to achieve full coverage of high mix inspection tasks contributing to industry 4.0 standards. This is the ultimate optical metrology solution for inspecting complex products in an automated production line.

Benefits

- AI-Based Automation: Using Artificial Intelligence and deep learning networks the KITOV.AI automates complex visual inspection tasks. It will rapidly identify both cosmetic (scratches, dents) and mechanical defects (missing screws, bent pins).

- CAD-to-Inspection: QC engineers can dramatically reduce setup time by defining inspection requirements directly on the CAD model. The software then automatically generates and optimizes the robot’s inspection path and camera poses for guaranteed full coverage.

- Subjectivity Elimination: Human subjectivity errors are removed using this fully automated system which is critical in safety-critical industries like aerospace and medical.

- Complex Parts Handling: The robot-based solution can inspect parts with complex geometries and is ideal for high-mix and low-volume production lines, accommodating parts up to 800 mm in diameter.

Applications

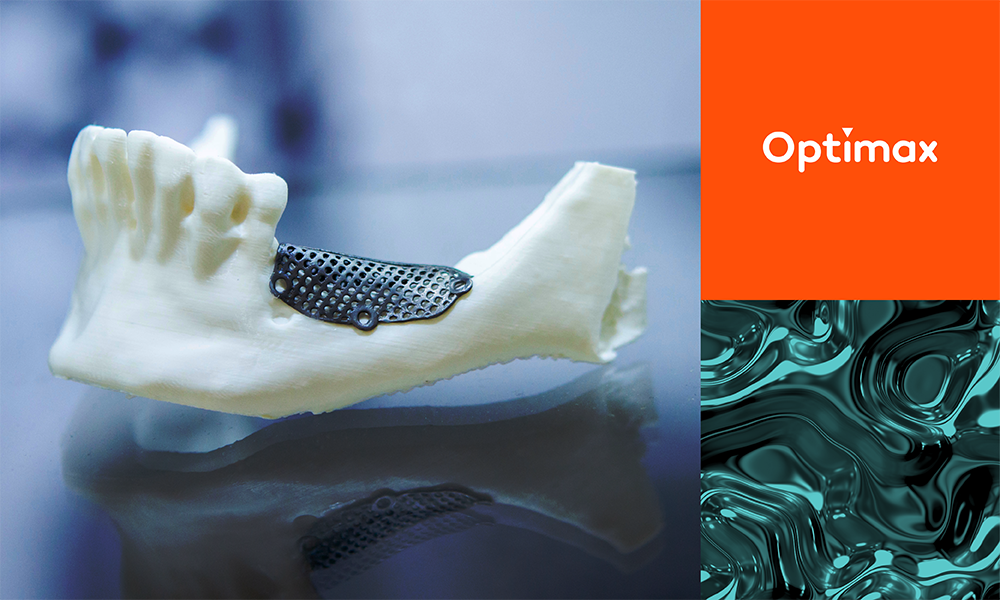

- Safety-Critical Components: Comprehensive inspection in aerospace, Medical and defence to find micro-cracks and assembly errors.

- Complex Electronics: Automated verification of assembly, wire bonding, and component placement on intricate electronic products.

- High-Mix Manufacturing: Quickly and efficiently adapting to inspect a wide variety of product models on the same production line.

- High-Volume Defect Detection: Inline inspection to detect defects like scratches, burrs, and flash, increasing throughput and reducing rejections.

If you’re looking to improve your optical metrology game in 2026, get in touch with us at Optimax for a full run-down of the tools that’ll grow your business.