What is a Cobot (Collaborative Robot)?

A cobot, short for collaborative robot, is a robot specifically designed to collaborate with human operators in a shared workspace without the need for traditional safety caging.

Unlike conventional industrial robots that are typically isolated, cobots are built with intrinsic safety features (like rounded edges, lightweight materials, and force-torque sensors) that allow them to detect human presence and either slow down or stop their motion automatically upon contact, ensuring a safe, direct human-robot interaction.

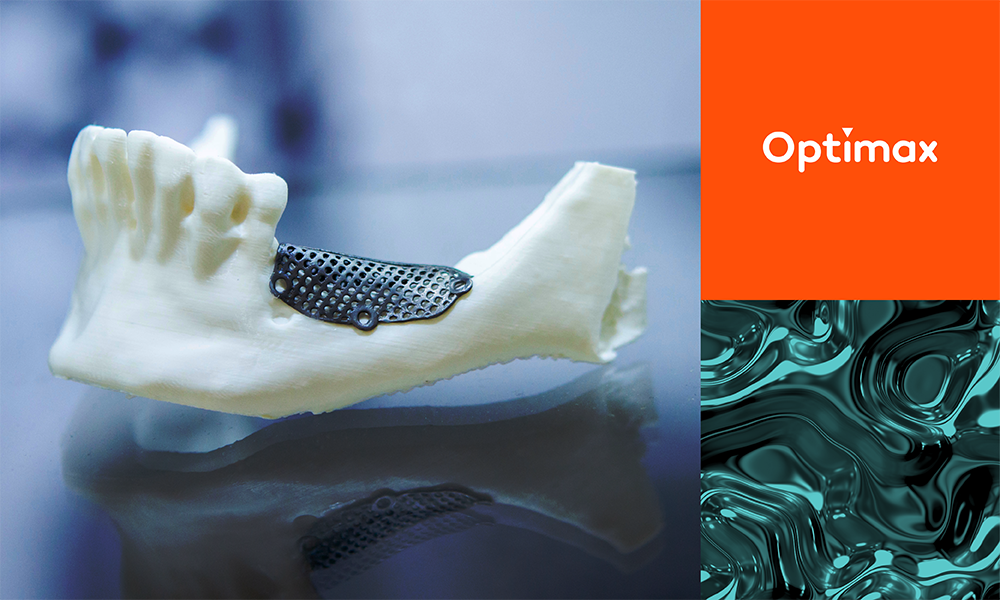

At Optimax, we supply two high-end industry cobots: The Alicona Cobot and the Optivue Cobot. Both are ideal partners for a range of applications across medical device manufacture, aerospace and automotive.

What are the Benefits of Cobots?

Cobots offer several key advantages, making them an ideal entry point for automation, particularly for small and medium-sized enterprises (SMEs):

| Benefit | Description |

| Increased Safety | They manage dull, dirty, and dangerous tasks, relieving human workers from strenuous, repetitive, or hazardous jobs, which reduces the risk of repetitive strain injuries. |

| Flexibility & Versatility | They are easily and quickly reprogrammable and redeployable to new tasks in various locations, making them suitable for high-mix, low-volume production. |

| Cost-Effectiveness | While the arm itself may vary in price, the overall system cost is often lower than traditional robots because they typically require minimal or no safety caging, reducing setup time and infrastructure expenses. |

| Enhanced Productivity | They take over repetitive, monotonous tasks, allowing human workers to focus on higher-value, more complex tasks that require human judgment, problem-solving, and quality oversight. |

| Smaller Footprint | Cobots are typically smaller and lighter than industrial robots, occupying less floor space and integrating more easily into existing production layouts. |

Are Cobots Different from Industrial Robots?

Yes, there are major differences in design, function, and purpose:

| Feature | Cobot (Collaborative Robot) | Industrial Robot |

| Purpose | To assist and collaborate with a human worker. | To replace human labour for speed, power, and high volume. |

| Safety Barrier | Minimal or none (designed to share a workspace safely). | Required (fencing/caging to isolate the robot from humans). |

| Speed & Power | Lower speed and force (limited to ensure safety). | High speed and high force (optimised for maximum throughput). |

| Payload/Size | Lower payload capacity (typically 3–30 kg); lighter/smaller build. | Very high payload capacity; heavy-duty, large build. |

| Programming | Easy, intuitive (often via hand-guiding or graphical interface). | Complex. usually requires specialised programming knowledge/engineering. |

Where Can You Use a Cobot?

Cobots are deployed in a wide range of tasks and are highly versatile. They are best suited for tasks requiring consistent, repetitive motion where direct human interaction or flexibility is needed:

Quality Inspection

- Holding a camera or sensor to perform automated or manual visual inspections with perfect repeatability. (e.g. blisks, engine blocks)

- Moving parts or products from one location to another with high consistency (e.g., from machine to automated measurement or placing components on a circuit board).

Other Applications

- Loading and unloading parts into CNC machines, injection moulding machines, or other processing equipment.

- Repetitively stacking products onto pallets for shipment.

- Performing simple, repetitive component fastening, screwing, or gluing.

- Light finishing tasks like sanding, polishing, or deburring.

Cobot Industries

While manufacturing and industrial environments are the most common users, cobots are expanding into various sectors:

- Automotive (e.g., sub-assembly tasks, quality control)

- Electronics (e.g., assembling delicate components, inspection)

- Food and Beverage (e.g., packaging, sorting, palletizing)

- Pharmaceutical/Medical (e.g., lab sample handling, sterile assembly)

- Small & Medium-Sized Manufacturing (where quick changeovers are essential)

How Easy are Cobots to Programme?

Cobots are designed for ease of use and accessibility, specifically so that operators without a deep background in robotics or coding can program them.

The two main user-friendly methods are:

- Lead-Through or Hand-Guiding: The user physically holds the robot’s arm and guides it through the required motion path. The cobot records the positions, and the user presses a button to save the “waypoint.”

- Graphical User Interface (GUI): Programming is done via an intuitive, tablet-like interface that uses drag-and-drop programming blocks instead of complex code. This allows for quick, on-the-fly modifications to the robot’s task.

Should I Invest in a Cobot?

Optimax’s cobot integration is not about replacing the human quality controller; it’s about giving them the ultimate assistant. The perfect analogy for an Optimax cobot solution is the World-Class Inspector and their Indefatigable Apprentice.

Flawless, Repeatable Execution

The cobot (loaded with an eviXscan 3D scanner or Bruker metrology sensor) takes over the tedious, repetitive tasks: picking up a component, loading it into a CMM, checking a hundred points, and repeating this for 5,000 parts. It never tires, never blinks, and never has an off day.

Precision Data Capture

The All-Seeing Eye: Optimax’s AI-driven visual inspection (like the Inspekto S70) and 3D scanning mounted on a cobot provide traceable, high-resolution data that a human inspector can’t achieve consistently. It eliminates subjective “pass/fail” decisions and reduces scrap and rework.

Human-Robot Collaboration

The World-Class Inspector: This frees the highly skilled human quality control engineer to be a Problem Solver, a Decision Maker, and an Innovator. They focus on the strategic tasks that machines can’t do:

Ease of Integration/Training | The Instant Team Member

Cobots are quick to program and easy to integrate, minimizing disruption. This is like adding a highly efficient, pre-trained employee who starts delivering results on Day One, instantly boosting team output. |

The Optimax Promise: Boosting Human Ingenuity

Optimax’s solutions don’t remove humans from the process; they elevate the role of the human expert.

By letting the cobot function as the perfectly precise, tireless apprentice, the skilled inspector can step away from the monotonous routine of checking the part and dedicate their valuable intellect to process improvement, technical expertise, and achieving zero-defect production.

Optimax is not selling automation – we are selling increased human productivity and the peace of mind that comes from flawless, traceable quality control providing a rapid ROI.