Casting inspections for automotive gearbox housing

Following the casting and machining of gearbox housings, the components need to be inspected to ensure that no damage or defects have occurred. The fastest and most reliable way to undertake these casting inspections is to work with an AI-guided system, the Inspekto S70.

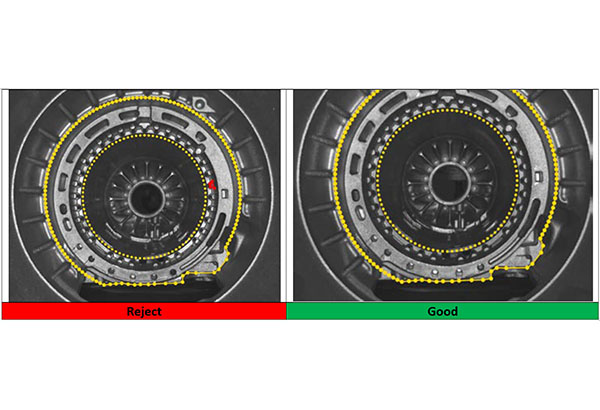

Finished gearbox housings are positioned by a robot for automated visual inspection. The Inspekto S70 looks for defects such as dents, scratches and castings issues; surface texture and shading differences are acceptable but issues with mating surfaces and bearing recesses will result in rejection for rework or scrap. When defects are found during the casting inspection, they are identified in red on the displayed or recorded image.

Why choose the Inspekto S70 for casting inspections?

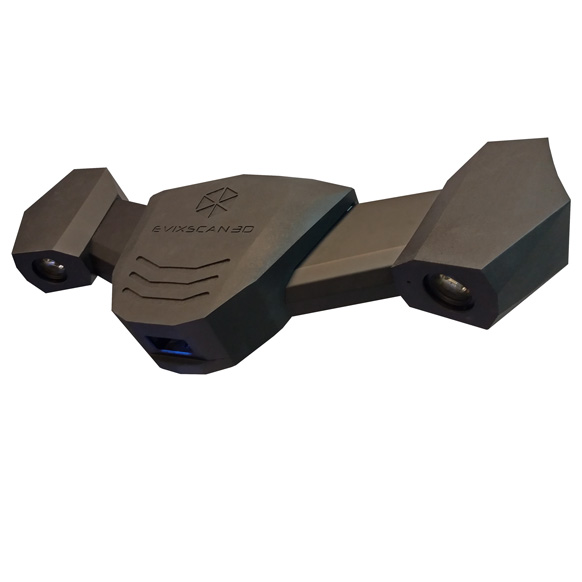

The Inspekto S70 is an out-of-the-box, plug-and-inspect autonomous machine vision system that does not require specialised machine vision or AI expertise. It is designed for immediate deployment, often within 20-60 minutes. No complex setup, camera calibration, lens selection, or lighting integration is needed.

It combines a unique electro-optical system with innovative AI technology to provide a visual quality inspection solution that is versatile, extremely easy to use, adapts to changes in the production line, and requires no machine vision expertise. Only 20 to 30 good samples are needed for set up and using multiple AI engines provides accurate, reliable and scalable visual inspection in 0.3 to 0.5 seconds. The system can be installed on the production line, either end-of-line or mid-line, and fully integrated with PLC or MES/ERP systems. Anti-reflection technology minimises the effects of challenging materials and lighting conditions – perfect for casting inspections within foundries.

It is cost effective providing a rapid ROI detects with real-time inspection defecting anomalies and missing components automatically. By removing the need for specialised expertise, it eliminates human error in quality inspection

Inspekto S70

The S70 can be used on many materials/components including Electrical Components, Metal, PCB’s, plastic, and rubber. This capability makes it an ideal solution for products such as injection moulded components where it can identify sink marks, pores, dents and flashing, electrical connectors-presence/missing/position, soldering on pcb’s, integrity & milling swarf in metal components, position and presence of labels, verification of coatings and O ring placement or missing.