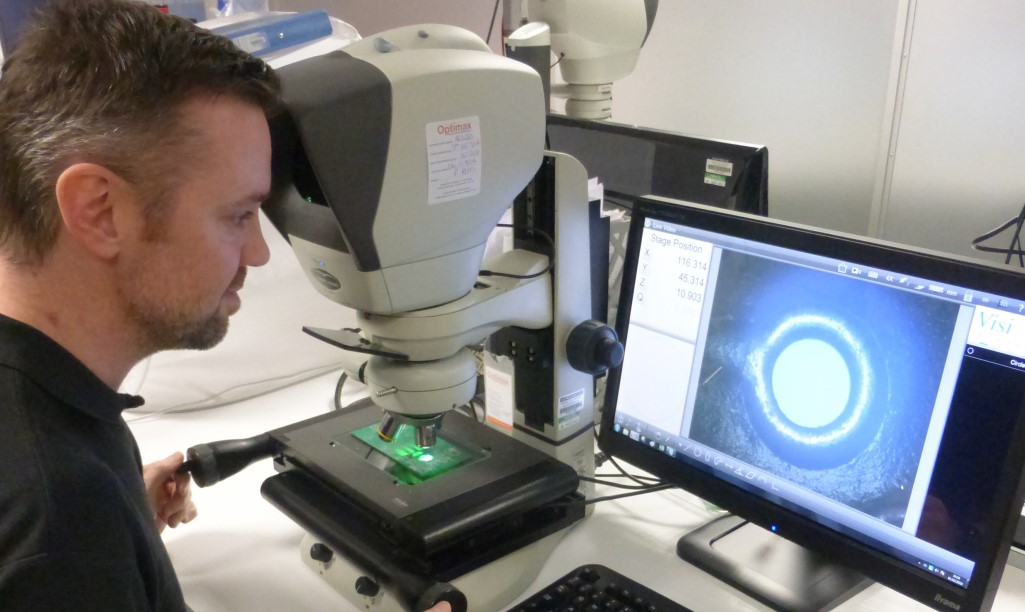

For R&D and Design:

Optimax provides advanced metrology solutions that help engineers validate new designs and materials. These solutions include non-contact measurement and 3D surface analysis. Testing material longevity, analysing performance under stress and understanding component structure can have a huge impact on the overall design of an airframe.

During Manufacturing:

We supply a range of quality control instruments, from handheld measuring instruments and optical comparators to automated vision systems designed to identify defects during the manufacturing of airframes and airframe components.

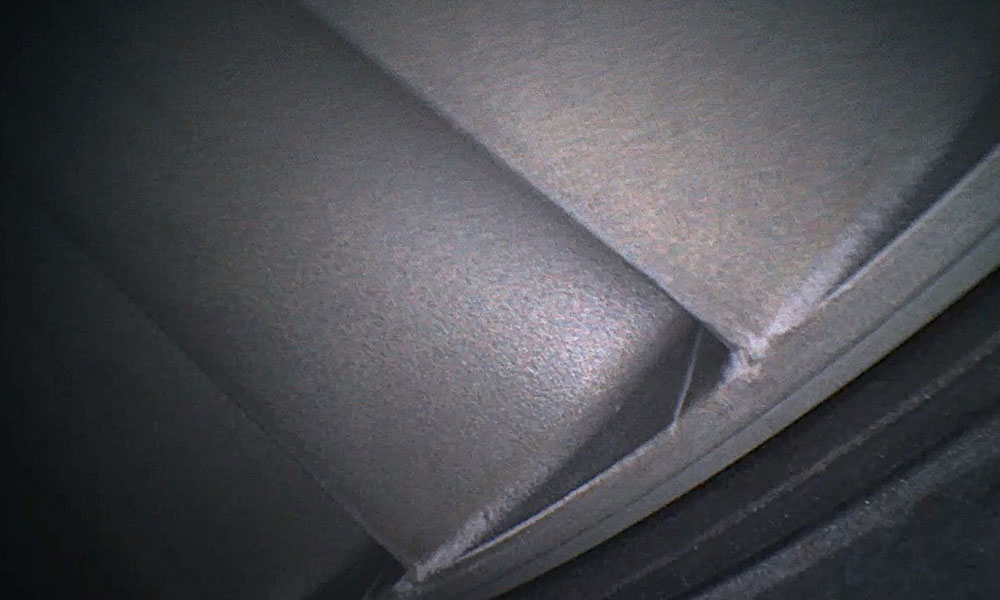

For Inspection and Maintenance:

We offer a wide selection of solutions for inspecting hard-to-reach areas. Our high-resolution borescopes and videoscopes are used for remote visual inspection (RVI) to identify issues such as: *Cracks and mechanical fatigue *Corrosion and rust *Foreign object damage (FOD) *Wear and tear *Debris and residue buildup *Fluid leaks *Damaged seals *Loose or missing parts. Time is money and therefore investing in reliable yet quick testing and inspection equipment, maintenance crews can reduce the amount of time an aircraft is grounded during routine inspections.