Medical Device Equipment Testing and Calibration

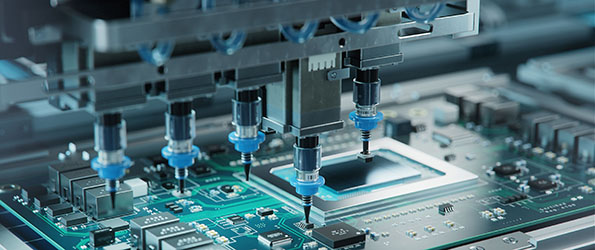

Accurate, evidence-based inspection and measurement are crucial in the medical device industry. Throughout design, manufacturing and clinical evaluation, each component must be validated to ensure precision, cleanliness and reliability. During clinical trials, devices often need to be recovered and examined for wear, material changes or potential failure points. These assessments must follow the highest possible standards.

Our medical device metrology instruments enable repeatable, traceable measurement down to the nanometre scale. Engineers can examine microscopic surface features, wear patterns and failure marks with clarity and confidence. Whether you require precision measurement metrology for early design work or high-speed medical production metrology for bulk manufacturing, Optimax supports every step of your development process.

For businesses requiring occasional verification or specialist inspection, our contract measurement service offers high-accuracy results carried out by skilled metrology engineers using state-of-the-art systems. It is ideal for one-off medical device inspection, testing and calibration tasks.