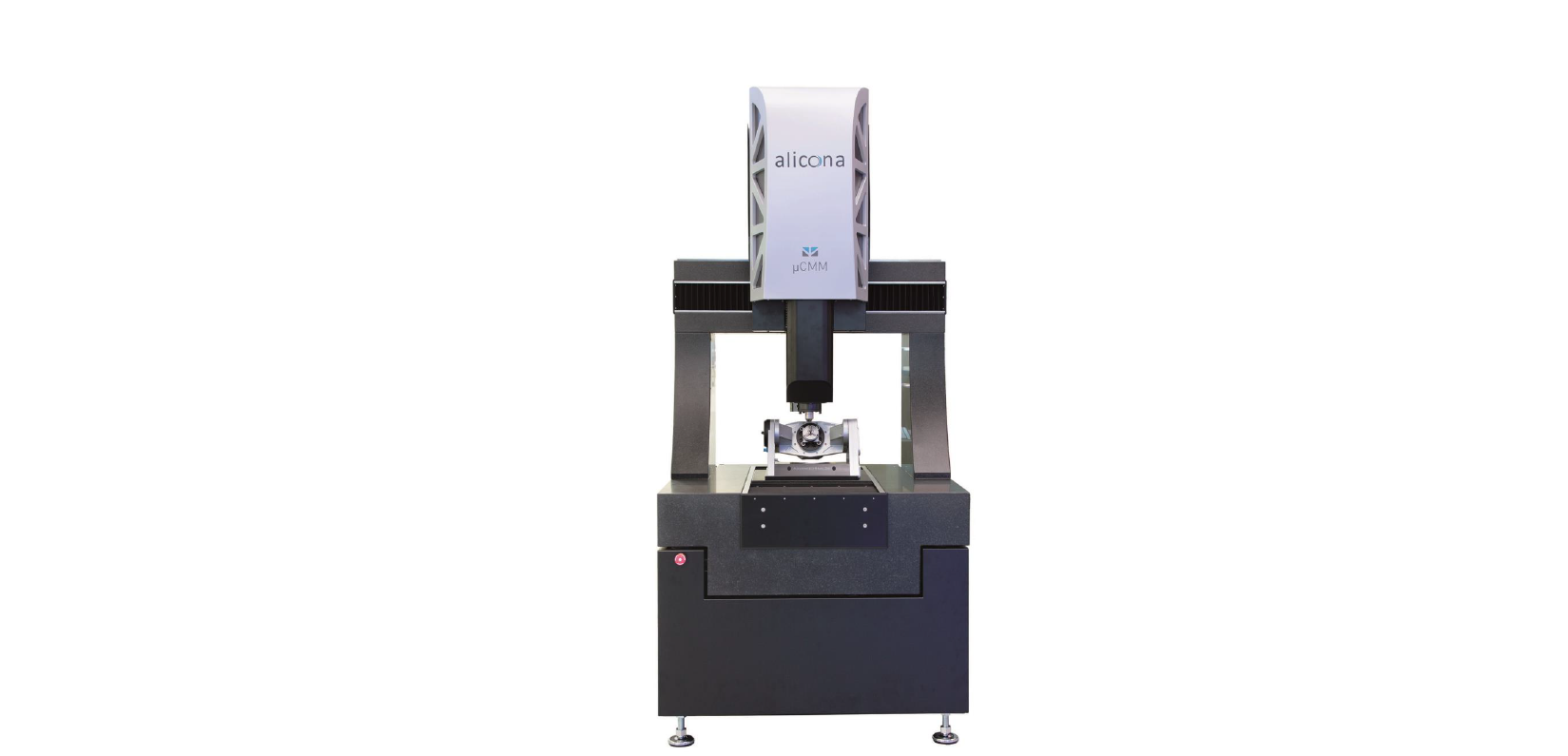

Medical Device Equipment Testing and Calibration Services

When it comes to the medical device industry, evidenced and accurate inspection and measurement during manufacture is crucial. Additionally, during the development and clinical trial phases where medical devices are recovered for assessment after use, testing the devices to look for changes and defects must be undertaken to the highest possible standards. Traceability of your inspection process can help to protect your business should any device unexpectedly malfunction.

At Optimax, a range of medical device metrology instruments enable traceable, repeatable measurement down to nanometre scale, as well as inspection of microscopic surface features, wear and failure marks. Our equipment can support your business throughout product design and development phases, all the way through to clinical trials and bulk manufacture. Should you need just one-off testing and calibration, our contract measurement service, provided by our team of skilled engineers, will provide you with high accuracy measurement, time and time again.