Helping Mansel Preforms meet exacting requirements

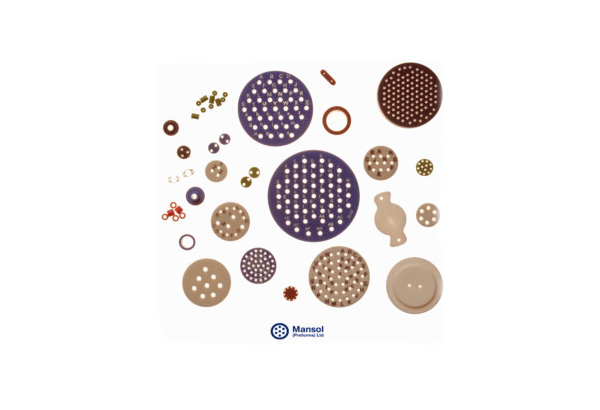

Suffolk-based Mansol Preforms manufactures glass and ceramic insulators, which are pre-formed into various shapes and sizes, depending on customer requirements. The majority are circular with multiple precisely located holes. They are crucial in performing safety-critical connectors, insulating each pin and ensuring accurate alignment. They serve a variety of applications, such as military, automotive, and aerospace, where a perfect hermetic seal and reliability are paramount. It is critical that the glass or ceramic insulator is manufactured to the precise dimensions needed and that the preforms are measured to ensure that the position of the holes and their relationship to the outer diameter are accurate. Customers in these regulated industries require comprehensive measurement reports, confirming that the dimensions are compliant and within permissible limits, and this was becoming more difficult using profile projectors and traditional paper overlays.

A digitised approach for precise analysis

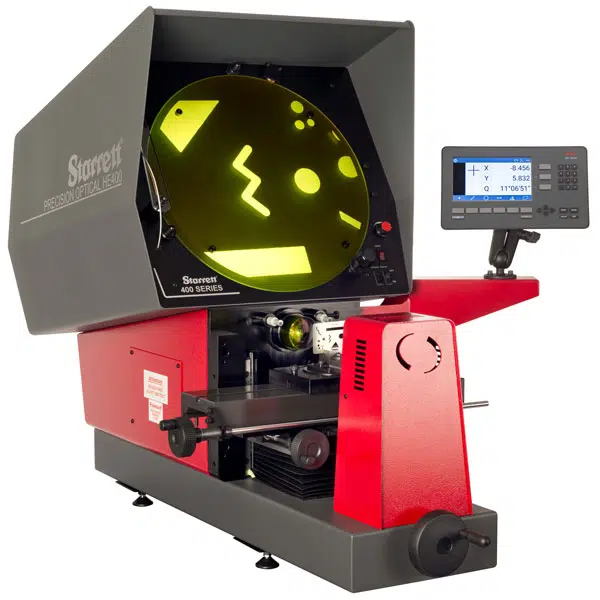

Mansol Preforms came to Optimax with these requirements, and after consultation and technical qualification, they recommended the Starrett HDV300 horizontal digital video comparator. The HDV is robust at home on the shop floor but also advanced enough to outperform traditional technology in the measurement room. It is configured like a horizontal profile projector but is fully digitized with a high-resolution sensor, LED surface, and profile lighting. The familiar, user-friendly format is flexible, ensuring that it can be used both manually for single and low-volume quick checks or programmed and automated, providing significant time savings and improved reporting outputs.

Starrett HDV300

We recommend the Starrett HDV300. In place of the traditional paper overlays, digital CAD files can be imported, providing immediate CAD data overlay and real-time comparative measurement. Parts can also be programmed into a library, and the touch screen software will recognise the part’s pattern and measure the holes’ position automatically. This offers a huge time-saving advantage over manual measurement for regularly manufactured parts. It is also extremely easy to switch between parts in the program library; it will even recognise patterns, matching the shape to a previously recorded sequence of measurements. The professional reporting outputs allow templates to be easily created, exported, and sent to customers, saving time and ensuring accuracy. The direct CSV Excel interface is also standard, as is SPC. In addition, Optimax calibrates the equipment UKAS, ensuring that it conforms to an internationally recognised standard and providing an independently audited verification process with well-understood measurement uncertainty.

Adam Kimber, Managing Director of Mansol Preforms, commented, “We are delighted with the new HDV300 and the measurement flexibility that it provides us. The library of parts we have been able to program has already saved us significant time, and we expect this to increase going forward. The library, combined with the ease and quality of reporting, has delivered a real return on investment for the company.”