What happens when an actuator fails?

Linear and rotary electrical actuators are used in many industries such as aerospace, automotive, robotics, manufacturing, medical and even in the home. In some of these industries, such as aerospace, the operation of these actuators can be safety critical, and failures need to be avoided. If an actuator fails, issues can range from poor performance to critical safety concerns.

Actuators have many purposes and can be used in primary and secondary flight surfaces, as well as landing gear systems and cargo doors. They can also be involved in engine speed and velocity control and therefore their performance is of utmost importance. If one were to fail, the electrical signals wouldn’t be converted into mechanical movement, for example, cargo doors may not open or aircon may become inconsistent. Other failures could be more catastrophic.

What is actuator testing?

There are a series of general inspection requirements that are fundamental for most electrical actuators regardless of their application. Visual inspection is a key part of the actuator inspection process with engineers checking for physical damage such as cracks, corrosion, wear, and electrical connections. Also, at the manufacturing/design stage, force and materials testing is required to fully understand component limits and longevity. Optimax supply a range of products suitable for inspection and test.

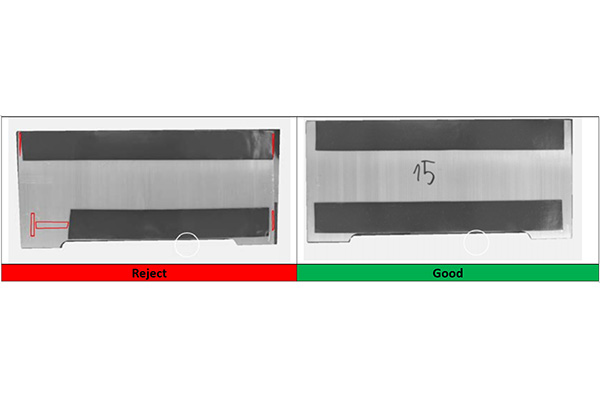

Inspekto S70

The S70 can be used on many materials/components, including Electrical Components, Metal, PCBs, plastic, and rubber. This capability makes it an ideal solution for products such as injection moulded components where it can identify sink marks, pores, dents and flashing, electrical connectors-presence/missing/position, soldering on PCB’s, integrity & milling swarf in metal components, position and presence of labels, verification of coatings and O ring placement