Optical 3D measurement of precision gears and splines

Precision gears and splines are used in many applications where reliable and accurate power transmission is important for both the function and reliability of a system. They may need to transmit high loads at high speeds while maintaining precise alignment meaning that the geometry, surface finish, mating surfaces and accuracy are important factors.

In the automotive industry there are many types of gears and splines used, some are less critical (such as plastic gears on windows) but many are important; especially in high performance cars, speciality vehicles and race cars such as F1 and Nascar. They feature in automatic and manual transmissions, differentials and steering systems where they are required to transmit smooth power from the engine to the wheels to maintain precise rotational alignment to ensure vehicle control and durability. This leads to a requirement for correct fitting between gears/splines to ensure there is no mechanical movement (backlash) between the mating parts.

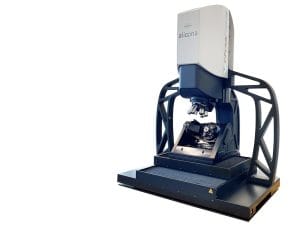

Non-contact optical measurement using the Bruker Alicona G6

The ideal solution for these measurements is a non-contact optical process that allows the accurate measurement of both form and finish over 360o. The Bruker Alicona G6 system offers this capability in in a single measurement system. Using the Focus Variation technology, the G6 is a combined form and roughness measurement system for use on gears and splines, meaning it can accurately measure the overall tooth profile, lead, pitch, and runout, as well as the surface roughness parameters (e.g., Ra, Rq, Sa, Sq) of the individual tooth flanks. This “two-in-one” capability saves time and eliminates the need for multiple instruments. It has a 5-axis capability allowing a comprehensive 360o data set of the component that ca be compared against CAD data. The innovative vertical focus probing allows the internal inspection of vertical flanks allowing measurement of full geometry of gear teeth and splines. These measurements are also critical in industries such as aerospace, defence, medical device, robotics, automation and machine tools and manufacturing.