Increasing efficiency of precision plastic moulding inspections

A leading designer, and manufacturer of precision technical mouldings, produce over eight million units per month. They specialise in the provision of high precision, tight tolerance mouldings in engineering polymers often with zero or minimum draft. They have expertise in coil bobbins & electrical insulation solutions for a variety of industries – each with unique measurement requirements.

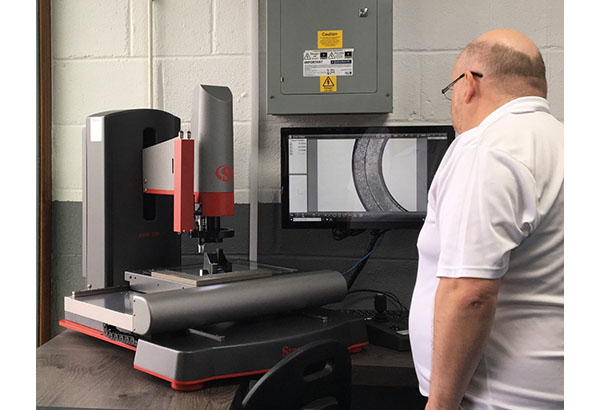

With long-term experience in the use of vision systems they needed a solution that would allow them to increase efficiency, volume of output and meet the highest level of quality assurance. The AVR300 CNC Vision System from Starrett provides accuracy, reliability, and versatility to meet these demands and can support plans for growth.

Why choose the AVR300 for plastic moulding inspections

The AVR300 stood out due to its versatility, an essential feature for a manufacturer meeting the differing requirements of numerous sectors. The Quality Manager explained that for automotive projects, the AVR300 is essential not only for Initial Sample Inspector reports but throughout the Production Part Approval Process. Black, white, and clear plastics mouldings can be particularly challenging to inspect and measure optically. The precision lens and advanced lighting options create high contrast on surface, edge, and blind hole features. The accuracy of the Starrett Vision range, with capability to measure optical height and depth down to a few microns meets all requirements.

In their own words? “The AVR300 is everything we needed in one machine. It’s invaluable for ensuring part conformance to meet sector requirements.”

AVR300

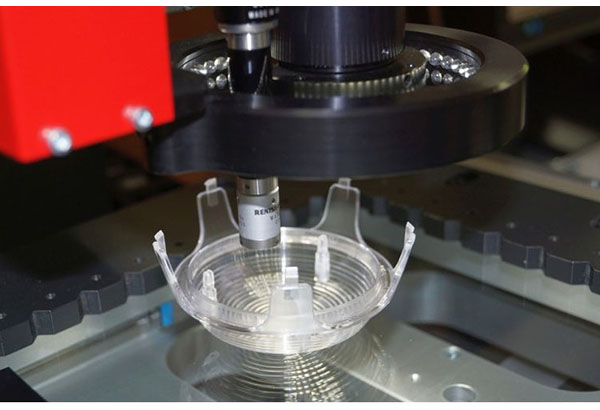

Optimax specified the AVR300, a CNC vision system fitted with an optional touch probe sensor and probe rack. The machine’s huge magnification range with 12:1 zoom optics and its segmented, height-adjustable LED ring light deliver optical measurement capability, while the touch probe enables accurate measurement of 3D features such as cylinders and cones that are out of the sensor’s line of sight.