4D InSpec Surface Gauge

Edge Break and Chamfer Measurement with 3D Certainty

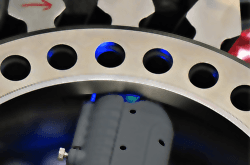

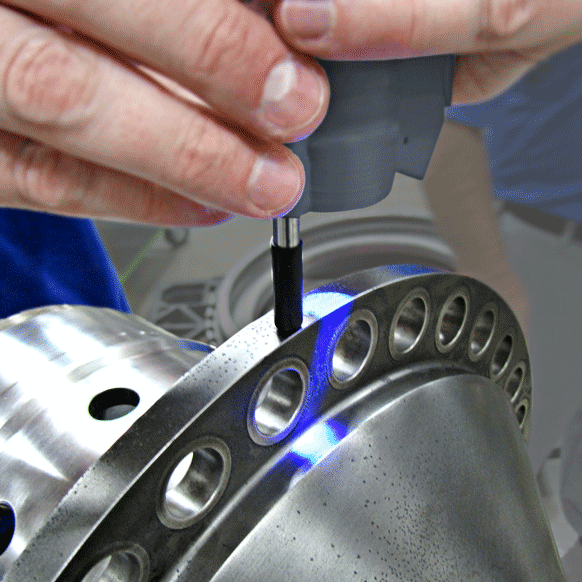

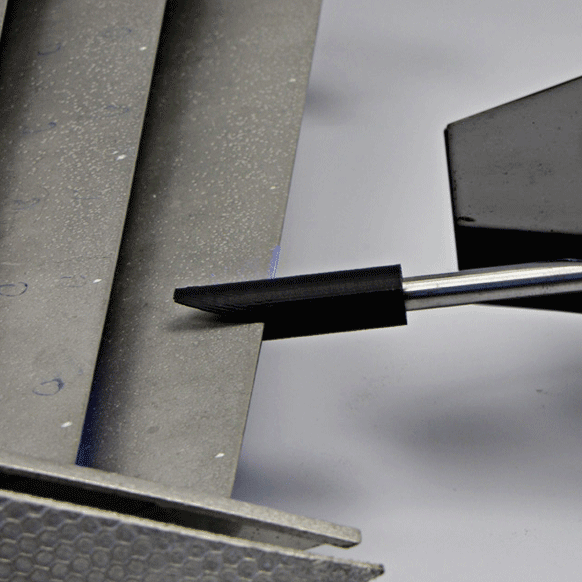

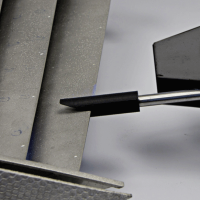

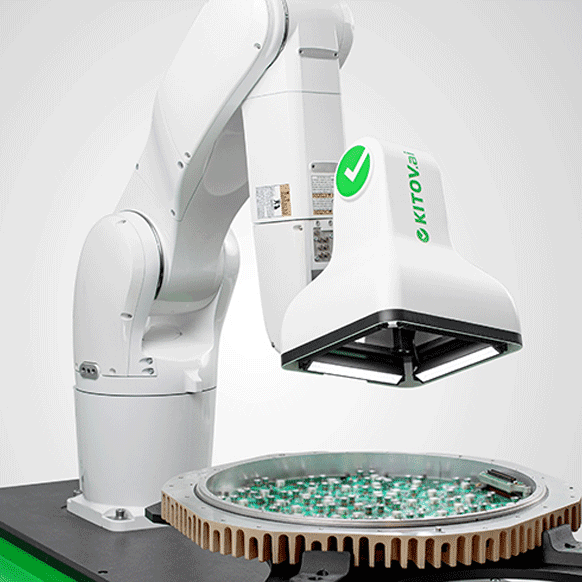

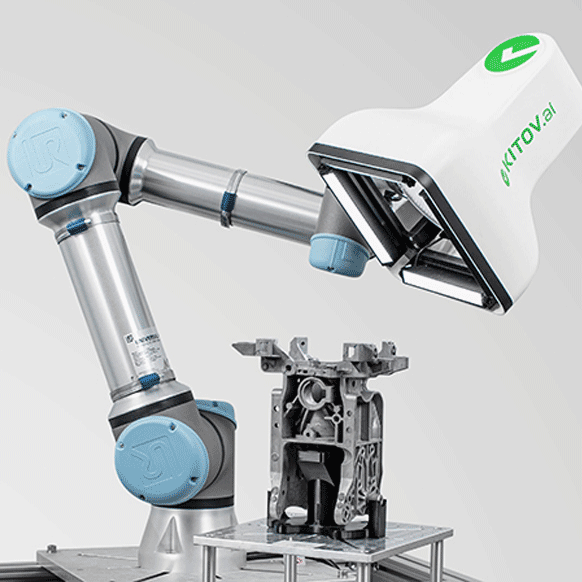

4D InSpec® is a handheld 3D surface gauge or used on a bench stand for edge break measurement. It can be mounted on a robotic manipulator for fully automated measurements of complex components and replaces subjective visual inspection of scratches, dings, dents, radii, dot peen, rivet depth and corrosion.

The 4D InSpec’s unique edge break measurement capability measures the subtle planes of adjacent surfaces and the chamfer or radius itself in three dimensions.

The system also provides micrometre-level resolution to precisely quantify and analyse a wide range of critical surface imperfections in less than 1 second. It manages common and problematic defects like dings, scratches, pits, dents, burrs, marring, radii, dot peen depth and rivet depth alongside broader surface finish deviations, such as corrosion, up to 2.5 mm deep or tall (up to 9mm with XL version).

The included software automatically bins defects in the measurement area, and 3D feature analysis calculates their height, volume, area, slopes, and location. Used in many industries such as aerospace (MRO), automotive, marine, precision manufacturing and medical devices it provides a rapid ROI.

The system supports easy data transfer to quality control systems via LAN, USB, or Wi-Fi for rapid, networked, pass-fail analysis.

The 4D InSpec® increases yield between 20-40% in machine shops and rework centres, contact Optimax on 01858436940 for a demonstration

Specifications

- Precision

- Portability and Accessibility

- Ease of Use

- Comprehensive Software

- Cost-effective

The 4D InSpec Surface Gauge is a portable, non-contact precision instrument that measures surface defects with micrometer-level resolution. It offers ease of use with one-button operation and comprehensive software for defect analysis. The gauge is rugged, affordable, and versatile, suitable for various environments, including factory floors and machine shops. It provides detailed 2D and 3D visualizations, making it ideal for quality control applications.

- 2.5 mm: Maximum depth/height of measurable defects and features

- 0.1" (2.5 mm): Depth or height range for quantifying surface features

- 1080p: Resolution of the HD touch-screen interface

- 8 hours: Operational time of the Li-ion rechargeable battery

- 3D: Dimensionality of measurements provided by the 4D InSpec

- 2D: Alternative view option for defect analysis

- One-button: Simplicity of operation

Case Study

“Gage capability” is a system’s ability to provide reproducible data over time, under changing conditions, and with different operators. The 4D InSpec is gage-capable for measuring defects such as nicks, scratches, and pits, and fine-scale features such as edge break, chamfer, and rivet depth. In this article we discuss how the 4D InSpec provides more repeatable data than other commonly-used inspection methods.