Optivu Cobot

Automate in-house metrology with the Optivu Cobot

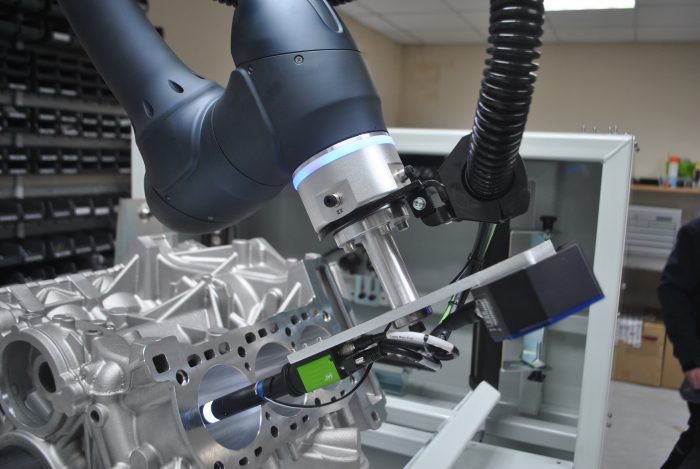

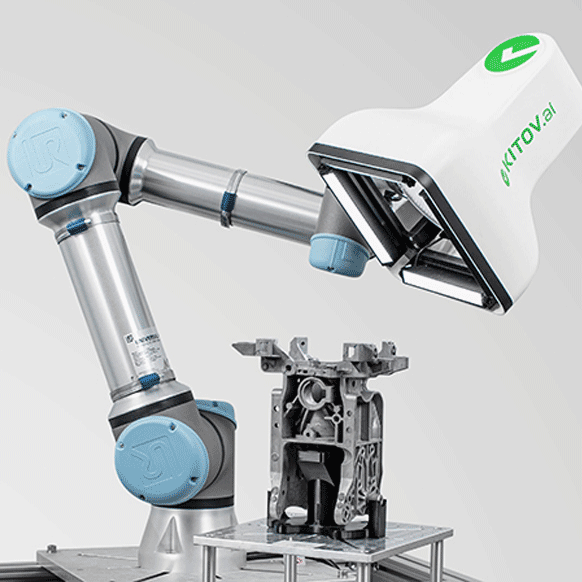

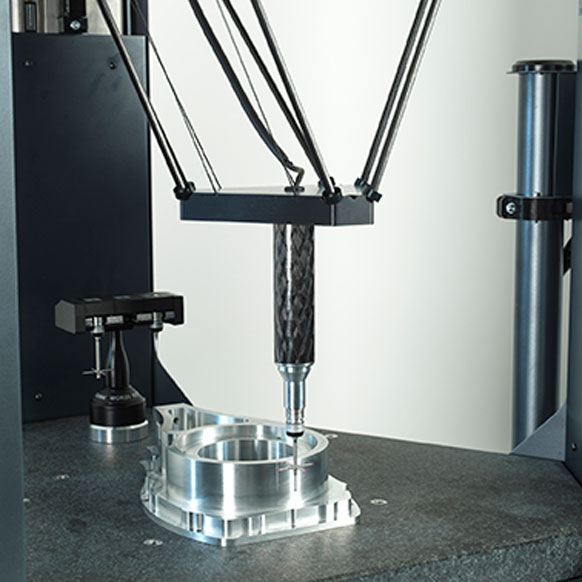

Collaborative robots, or cobots as they are known, are becoming increasingly popular in precision manufacturing as a method to automate and accelerate in-house metrology tasks. The Optivu has been designed to automate an extensive range of inspection tasks, reducing human intervention and improving productivity. It can be used both inline and as a standalone automation tool making it suitable for a huge range of precision applications.

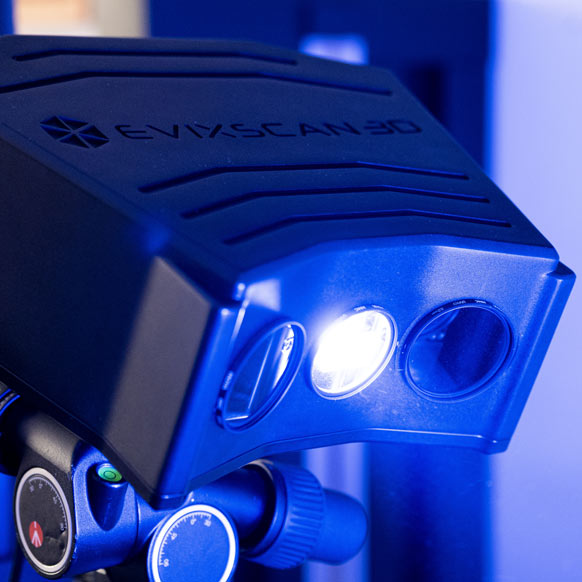

It can effectively be used with Bruker Alicona 3D optical sensors, Evixscan 3D scanners and Inspekto AI based vision inspection systems. Optimax will work with a customer to provide an automated measurement solution.

The Optivu Cobot is useful in many industries including automotive, electronics, general machinery, pharmaceuticals, packaging and others. On average the Cobot enhances work speed by around 10% and is competitively priced for excellent ROI.

If you’re looking for a reliable and accurate cobot to improve your production metrology, get in touch to find out more about the Optivu Cobot.

Specifications

- Collision detection technology

- Faster joint speed to enhance productivity

- Force control accuracy of Force Torque Sensor (FTS) to higher performance

- Either 5Kg or 9KG payload

- Solid control platform guarantees stable performance, real time control and high speed communication

- Software enables robot teaching, along with a wide range of programming actions

- Inspection

- Machine Tending

- Pick and Place

- Packaging

- Glueing and Bonding

- Polishing and Deburring

- Assembly

Case Study

Test case study content