The digitization of manufacturing is seen to herald a new industrial age, industry 4.0. A manufacturing phase of unparalleled connectivity and digitisation.

Industry 4.0 was actually devised as a strategic initiative by the German Government in 2011. Since then, the term has come to define what is seen as a global shift in manufacturing practices. The German Government’s 10 – 15 year industrial plan aimed ‘to drive digital manufacturing forward by increasing digitisation and the interconnection of products, value chains and business models.’ (Europa EU, 2017) Now a global movement, its implications for the metrology market cannot be ignored.

Are we already seeing an impact in the metrology sector?

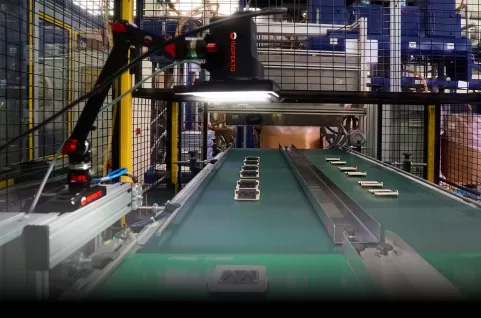

Over the past twelve months alone Optimax IIM Ltd. have seen automated metrology solutions dominate sales with a 30% growth in demand. Through the adoption of automated or semi-automated metrology devices, ‘companies can benefit from higher repeatability in their inspection process, increased inspection frequencies, and faster response back into the process through a variety of techniques, including direct machine tool feedback.’ (Everling, 2014) Precision pressing company Brandauer, recently purchased from Optimax, the automated L2 Starrett Force Measurement device for measurement of their propriety EloPin press-fit solution. The size of the EloPin (less than 1 mm in diameter) and the need for pin-hole alignment during insertion, necessitated an automated measurement solution. Fully programmable and intuitive to use, the L2 software supports Brandauer’s efforts to optimise their production processes by allowing use by shop-floor staff without training.

Are contemporary metrology devices equipped for Industry 4.0?

It is widely thought that it is in the potential for complete connectivity where the greatest benefits of digitisation can be found. In industry 4.0 all areas of the manufacturing process could exist on the same network – forming an Internet of Things (IoT). This could place quality control at the centre of the production process, ensuing the production of good parts. Bruker Alicona explain that in Smart Manufacturing:

‘Product systems, machines and measurement technology form a closed loop in constant communication…if the measuring sensor detects that the component is faulty, this information is fed into the production circuit, which adapts accordingly.’ – Bruker Alicona.

Overcoming the existing disconnect between devices remains a competitive frontier for innovation in metrology, with the sector as a whole yet to fully realise the connectivity of the Internet of Things. Striving towards Smart Manufacturing, Bruker Alicona devices can be flexibly integrated, while their high-resolution optical measurement sensors create a digitized system. This is all linked using an intelligent interface technology. Rather than a separate offline, measuring room, as is relied upon in so many manufacturing plants. These innovations move quality assurance to the centre of production. Complex measurements are executed quickly and efficiently.

Is the shift to Industry 4.0 the end for manual metrology?

Manual metrology devices still sit comfortably in the reliable and repeatable processes of many of Optimax’s clients. It is not just about familiarity – manual devices often offer a lower initial investment, often with less time and resource needed during the initial training phase. They can be more robust and less susceptible to operator damage, with fewer moving mechanical parts to damage.

So while the shift to the fourth industrial age is undeniable, it’s a steady process that’s unlikely to completely replace the metrology equipment of the third industrial era, and makes continued investment at all levels of device complexity essential.