In the era of Industry 4.0, where global competition, shorter product life cycles, and “zero-defect” policies are becoming the standard, manufacturing companies face a fundamental question: how to work faster, more accurately, and more efficiently? The answer is not to work harder, but smarter – by using tools that provide precise, objective data.

Implementing a 3D scanner is a strategic business decision, not just an innovation. It’s an investment in digital transformation that delivers tangible benefits at every stage of the production process. EviXscan 3D, have spent years creating technology that not only measures but, above all, provides a real competitive advantage. Here is what you can gain by introducing 3D scanning solutions to your company.

Uncompromising Quality Control with 3D Scanners

Traditional tactile measurement methods, such as CMMs, check only selected points, leaving a huge margin for undetected errors. A structured light 3D scanner captures millions of measurement points in seconds, creating a complete digital map of the entire object.

What do you gain?

A complete geometric picture. Instead of a few points, you get a dense point cloud that allows for an in-depth analysis of deviations across the entire surface compared to the CAD model.

Early defect detection. Casting flaws, post-welding deformations, or injection mould irregularities become visible immediately, allowing for process correction before costly losses are generated.

Reliable reporting. Automatically generated, color-coded deviation maps are intuitive and understandable for everyone – from the engineer to the end customer. It’s objective proof of quality that builds trust and strengthens your brand.

Acceleration You Can See in Your Results: Reverse Engineering & Prototyping

Time is money – nowhere is this truer than in R&D and new product introduction. 3D scanning radically shortens processes that once took weeks.

What do you gain?

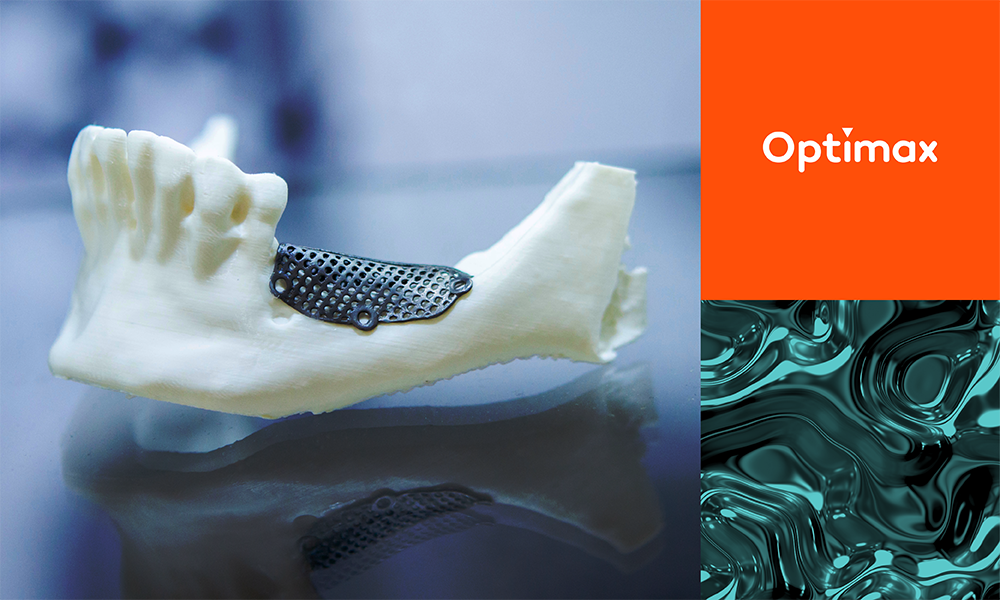

Instant reverse engineering. Need to reproduce a part that lacks CAD documentation? Want to modernise an existing component or create a perfectly fitted element? Scanning provides a precise 3D model that serves as a ready-made foundation for further design work.

Streamlined prototyping. Scan a physical prototype, make changes in CAD software, and print a new version on a 3D printer. This iterative process allows for faster testing and product refinement, minimising costs and shortening the time-to-market.

3D Scanning Automation – Your Key to Scalability and Repeatability

Imagine a quality control station that operates 24/7, without fatigue, and with a guarantee of the same, highest precision for every measurement. This isn’t a vision of the future; it’s a reality made possible by integrating eviXscan 3D scanners with industrial robots.

What do you gain?

Increased throughput. An automated system can measure hundreds or even thousands of parts per day, eliminating bottlenecks in the production process.

Unwavering repeatability. A robot always follows the same path and performs measurements identically, eliminating the risk of human error and ensuring consistent results.

Optimisation of human resources. Your top engineers and quality specialists can focus on data analysis and process improvement instead of performing repetitive, manual measurements.

Savings You Can Count: Cost Reduction and Maximising ROI

Investing in precision metrology is one of the fastest-returning investments in the industry. Every error detected at an early stage translates into real, tangible savings.

What do you gain?

Less production waste. Immediate feedback on quality allows for real-time adjustments to machine parameters, drastically reducing the number of defective parts.

Reduction of costly complaints. By guaranteeing product compliance with specifications, you minimise the risk of returns, warranty repairs, and reputational damage.

Optimisation of tool wear. Regular scanning of moulds, dies, and tools allows for monitoring their wear and tear, enabling you to plan maintenance before their condition affects production quality.

Data-Driven Confidence in the Digital Age – Make Decisions Based on Facts

In a digital factory, there is no room for guesswork. You need hard, objective data that forms the foundation for key business decisions. A 3D scanner is the gateway to creating a “digital twin” of your products.

What do you gain?

A single source of truth. The digital 3D model becomes a universal reference point for all departments – from designers and technologists to quality control.

In-depth analysis. Scan data can be used for advanced analyses, such as FEA simulations, wear analysis, or predicting component lifespan.

Versatility and the Confidence of an Optimax Partnership

eviXscan 3D understand that there is no one-size-fits-all solution. That’s why they offer a portfolio of scanners – from the Fine Precision series for micron-level measurements of small parts to the Heavy-Duty line for scanning large objects.

What do you gain?

Local expert support. Our team is on-site, ready to help implement the solution, train your team, and provide top-tier technical support.

A tailor-made solution. We help you select not only the right scanner but the entire ecosystem – software, accessories, and potential automation – perfectly suited to your unique needs.

In summary, implementing an eviXscan 3D scanner from Optimax is an investment in the certainty, speed, and intelligence of your manufacturing processes. It is a step towards the factory of the future, where every decision is based on precise data.

Want to see how our scanners can revolutionise your quality control? Contact us to schedule a free demonstration.