A borescope, also known as an endoscope, is a specialist tool used within optical inspection to visually inspect internal areas difficult or impossible to view with the naked eye. There are two types of borescopes, rigid and flexible, flexible ones can be either video based or use eyepieces and/or cameras and rigid ones also use eyepieces or cameras. Flexible borescopes have a long thin optical tube of different lengths and diameters which transmit light and have miniature cameras in the tip to take images of the feature being inspected. The rigid and semi rigid borescope versions have rigid fixed tubes.

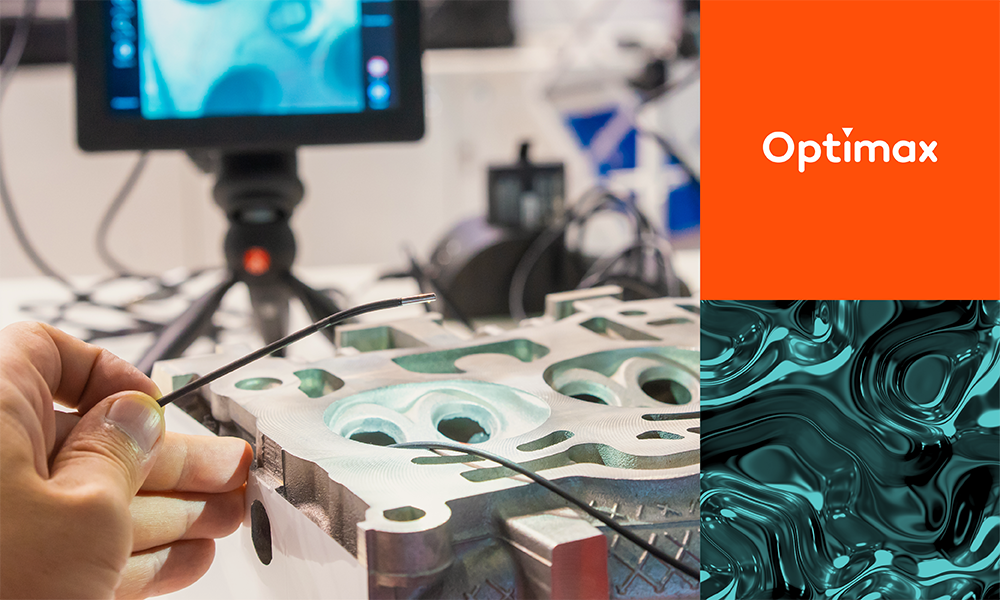

Borescopes allow users to view and assess the internal components of machines, pipes, engines and other confined or obstructed areas without needing to dismantle or take apart the equipment. As the items being inspected are internal borescopes come equipped with LED lighting to help illuminate the inspection area. The tubes can either have lenses looking straight ahead or at 90 degrees.

Where are Borescopes Used?

Borescopes are commonly used across a variety of industries including automotive, aerospace, plumbing, precision manufacturing and industrial maintenance. The ability to inspect internal components without disassembly saves time and money and helps prevent damage or wear caused by regular maintenance checks. At Optimax, we supply borescopes into complex markets where clarity and durability are key.

Key Features Borescope

Rigid or Flexible Tube

The tube is designed to be narrow enough to fit into tight spaces and long enough to reach deep into the area of interest. With flexible borescopes, a bundle of fibre optic cables is used to transmit light and images. This can cause issues with fragility, however, at Optimax all our flexible borescopes re fitted with heavy duty sleeves and are very sturdy. The choice of tube depends on the application and choice between

- Rigid borescopes are used for straight-line viewing into areas where a straight path to the inspection area is available.

- Flexible borescopes (also called endoscopes, fiberscopes or videoscopes) can bend and curve, allowing for greater manoeuvrability in complex spaces, such as inside machinery, piping systems or aeroengines.

- Tube/Probe Size many different options are available to be selected according to requirement

Optimax Guide: Rigid or flexible borescope, which one is right for you?

Lens or Camera System

Borescopes have two main types of visual systems. This display or eyepiece allows the user to monitor the inspection process in real-time, and in the case of video borescopes, capture images or record video for further analysis or documentation.

- Optical Borescopes: These rely on a series of lenses inside the tube to transmit the image from the area being inspected to the operator’s eyepiece see Hawkeye Pro Slim . These are typically older or more basic borescope models.

- Video Borescopes (Videoscopes): These use a tiny camera at the tip of the borescope to capture real-time video or images, which are transmitted to an external display or screen. This allows for more advanced imaging, including the ability to record and capture photos for later analysis, see Hawkeye Q2 Some models even allow for wireless transmission to a remote device, such as a tablet or smartphone.

Video borescopes are most popular today due to their ease of use and image capture capabilities. Our Hawkeye range of videoscopes and borescopes includes all types of instruments.

Light Source

Because many of the areas that need inspection are dark or have limited visibility, borescopes are equipped with a built-in light source. Most modern borescopes use LED lights at the tip of the instrument, though older or specialised models may use fibre optic lighting. These lights illuminate the inspection area, making it easier to capture clear, detailed images or video.

Articulation (Steering Capabilities)

Many advanced flexible borescopes, come with articulation controls. These controls allow the operator to bend and steer the tip of the borescope in various directions, providing a wider and more detailed view of the area being inspected and is controlled from the handset. Articulation is particularly useful when navigating around corners or inspecting complex, multi-dimensional spaces such as aircraft engines, HVAC systems or industrial equipment. See Hawkeye E Series

Applications of a Borescope

Borescopes have a wide range of applications across various industries due to their ability to inspect difficult-to-reach areas without the need for disassembly.

- Automotive Industry: Borescopes are used to inspect engine cylinders, fuel injectors, exhaust systems and other internal components. This allows mechanics to diagnose problems like carbon buildup, wear, or blockages without having to take apart the engine.

- Aerospace and Aviation: Aircraft engines, turbines and other complex systems are regularly inspected using borescopes. This is crucial for ensuring that no internal damage or wear compromises the safety of the aircraft.

- Plumbing and Pipe Inspection: Plumbers use borescopes to check for blockages, corrosion, or leaks inside pipes. These inspections help diagnose issues without the need to dig up or dismantle the plumbing system.

- Industrial and Manufacturing Equipment Maintenance: Borescopes are invaluable for routine maintenance checks of heavy machinery, ensuring components are functioning properly and identifying areas of wear or potential failure before they cause breakdowns.

- Security and Law Enforcement: Borescopes are sometimes used in security applications for inspecting suspicious objects, devices or confined spaces during bomb disposal operations or tactical investigations.

See below a video of a borescope inspecting a welded tube.

Non-invasive visual inspection with borescopes

A borescope/videoscope is a versatile essential tool enabling the visual inspection of areas that are inaccessible, allowing for detailed observation and maintenance. As technology continues to advance, borescopes are becoming more sophisticated, offering higher-quality imaging, greater flexibility, and enhanced articulation for more accurate and detailed inspections.

Borescopes provide a non-invasive way to see inside tight or confined spaces, saving both time and effort while reducing the risk of damage during the inspection process.