Tactile metrology, which has been used in Industry for many years, relies on a physical probe contacting the objects surface, whereas optical metrology uses non-contact methods of data acquisition such as light and laser.

What is Optical Metrology?

Optical metrology is based on the science that uses light (such as structured light, white light, or lasers) to collect data from a surface that can be used to measure geometric and surface characteristic data from an object. It is a non-contact technique meaning that the measurement device never makes physical contact with the object.

Benefits of Optical Metrology

- Non-Contact: Many of the objects that are measured could be damaged or deformed with physical contact (e.g. precision surfaces, soft and delicate products). Non-Contact measurement removes this risk.

- Measurement Speed and Data Density: Most Optical methods can capture millions of data points of an entire surface in seconds, providing a comprehensive 3D map of a surface on which selected measurements areas can be chosen.

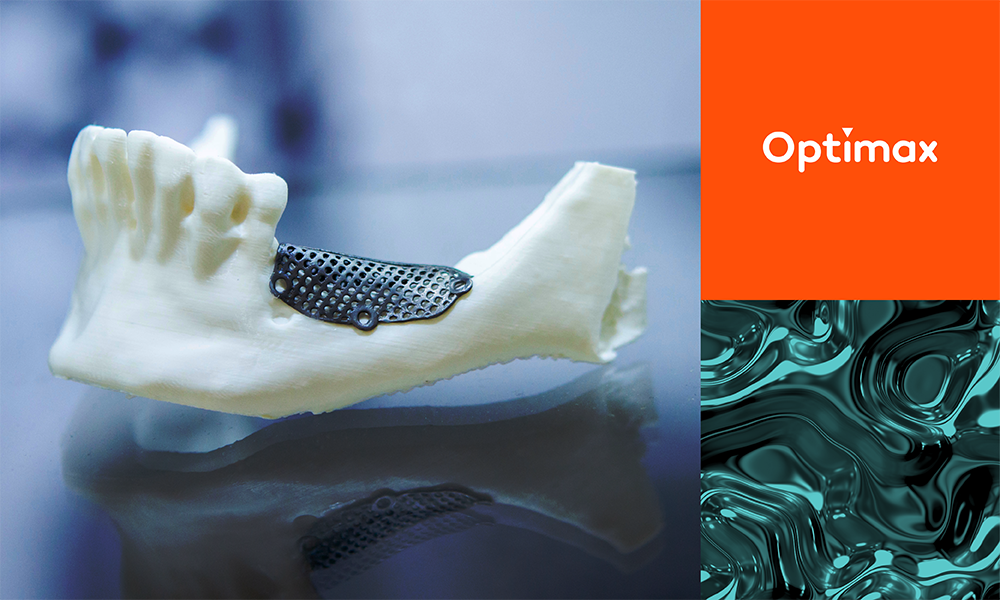

- Reverse Engineering and Quality Control: Optical systems are Ideal for the rapid digitising of complex freeform surfaces for comparing the measured part to the CAD model or creating a CAD model from an undocumented part.

- No Probe Compensation: As there is no physical probe no allowance is needed to account for the probe’s radius or potential wear.

- Probe size restricts measurement: If a probe size is 0.2mm it cannot measure anything less, optical metrology measurements do not have this restriction, making it ideal for e.g. small surface cracks.

- Environmental Sensitivity: Modern optical systems, especially those based on Focus Variation are not sensitive to ambient conditions such as vibration, temperature fluctuation, or ambient light

- More Representative Measurements: Any tactile method can only be a point or line-based measurement. Whilst this is ok for dimensional measurement it is not ideally suited for surface measurement, Optical Metrology is areal based indicating that this is a true measure of the surface and not of a single line or point on the surface.

Disadvantages of Optical Metrology

- Surface Sensitivity: Measurements on some techniques can be negatively affected by highly reflective (glossy), transparent, or very dark/black surfaces. This is not true with techniques such as Focus Variation but on some techniques Pre-treatment (e.g., spraying with an anti-glare powder) may be necessary.

- Measurement Range: Tactile CMM’s can measure larger objects than current Optical systems.

- Accessibility: Some techniques may struggle to measure features that are deeply recessed or have steep slopes due to shadowing or line-of-sight limitations. The Focus Variation technique has overcome these issues whereas products based on fringe projection or Structured Light are unable to do this/

Optical Metrology Applications

Optical metrology provides a versatile non-contact solution for quality assurance, R&D and reverse engineering. It is a powerful tool used across all industries (e.g., automotive, aerospace, medical, electronics, and precision manufacturing).

It provides precise, traceable 3D measurement of component features. Its core capability is in the robust measurement of dimension, position, shape, and surface roughness of components of varying materials and sizes, including the ability to measure round and cylindrical items and inside small holes. This optical approach is uniquely suited to reverse engineering, allowing the rapid creation of highly accurate 3D data models from existing physical parts.

Advantages Over Tactile Metrology

The benefit of optical metrology over traditional tactile (contact) relate to speed, detail, and non-contact measurement. Optical systems capture millions of data points across an entire surface in seconds; this results in faster results and full-area coverage that tactile probes cannot match. It is also ideally suited for the measurement of soft, fragile, or high-precision components without risk of damage or deformation. Optical metrology is also ideal for measuring micro-geometries and surface roughness using the same data in the same machine.

What is Tactile Metrology?

Tactile metrology is a measurement technique that involves physical contact between a stylus or probe and the surface of the object to provide measurement data. This is typically done using machines such as coordinate measuring machines (CMMs) or stylus- (or line-) based roughness measurement systems.

Benefits of Tactile Metrology

- High Absolute Accuracy: It is agreed that a CMM offers the highest absolute accuracy over a large geometric measurement range. And is ideal for large demanding, tight-tolerance parts.

- Material and Surface Independence: A CMM will provide reliable accurate measurements regardless of the object’s reflectivity, transparency, or colour.

- Accessibility: A CMM probe measures in the X,Y & Z range and can often reach recessed feature such as bores, deep holes, or complex internal geometries that maybe inaccessible to line-of-sight optical scanners.

- Standardisation: The technology is mature, well-established, and supported by robust international standards for measurement and calibration.

- Roughness Measurement: A CMM cannot measure surface roughness, and this can be made using a tactile profilometer where a stylus is moved across a surface. It is suitable for measuring 2D roughness parameters such as Ra, Rz etc, unsuitable for soft products.

Disadvantages of Tactile Metrology

- Slower Data Acquisition: Measurements are acquired point-by-point, which is significantly slower than optical methods and difficult to produce for high-density data or full-surface topography.

- Risk of Damage: Physical contact from the probe/stylus can potentially damage or deform parts made of soft, delicate, or flexible materials.

- Wear and Calibration: Probes are subject to wear and require careful probe qualification to allow for wear.

- Limited Data Density: The data collected is point-based or profile data, which may prevent a complete inspection of complex freeform surfaces.

Tactile Metrology Applications

Tactile metrology is a well-established measurement technique providing a well solution for quality assurance & R&D. It is a powerful tool used across all industries (e.g., automotive, aerospace, medical, electronics, and precision manufacturing). It provides precise, traceable 2D measurement of component features. Its core capability is in the robust measurement of dimension, position & shape.

Advantages Over Optical Metrology

The benefit of tactile metrology over optical metrology relates to the size of the object being measured (you do not need a 1M travel to measure a 300mm object) so are ideal for larger objects and absolute accuracy requirements. They can measure large internal features such as deep bores, internal gear teeth, slots, and undercut geometries

It is a well-established technology and standards and have been used in quality control for a long time, leading to widespread acceptance and a robust framework. Tactile methods, particularly stylus profilometry for surface roughness, are widely accepted as the industry standard, and their 2D profile-based measurements are often required for established ISO and DIN standards compliance.

Optical vs Tactile Metrology Table

| Feature | Optical Metrology | Tactile Metrology |

| Measurement Principle | Non-contact (uses light, e.g., laser, structured light) | Contact (uses a physical probe/stylus) |

| Data Acquisition | Fast, full field (millions of points/sec) | Slow, point-by-point or profile (scans a line) |

| Data Type | High-density 3D data (point clouds, meshes) | Low-to-medium density 3D coordinates, 2D profiles |

| Risk of Part Damage | None (non-contact) | Possible on soft or delicate materials |

| Surface/Material Impact | Sensitive to reflectivity, transparency, and colour

(Method Dependent) |

Insensitive (works on most surfaces) |

| Highest Accuracy | Very High, Micron range or better | Extremely High, Micron range or better |

| Best For | Complex freeform shapes, rapid inspection, soft parts, round parts

Micro Engineering |

Tight tolerances, deep features, internal geometries |

| Key Instrument | 3D Scanners, Interferometers, Optical CMMs | Coordinate Measuring Machines (CMMs) |

| Ideal Industries | Used across all Industries | Used across all industries |