What is a hydraulic pump?

The principle of a hydraulic pump is quite simple; it is used to convert energy from a power source into hydraulic energy by generating fluid flow. They are used in areas such as aerospace, automotive, marine and manufacturing. The three most common types are Gear Pumps, Vane Pumps and Piston Pumps and would be chosen according to their specific application. In aeroplanes, hydraulic pumps will often be used in landing gear, flaps and brake systems alongside control valves, actuators and reservoirs. A hydraulic pump failure could have catastrophic impact on the aeroplane’s safety and therefore strict testing and inspection routines must be upheld.

What does a hydraulic tester do?

During manufacture, the component parts of a hydraulic pump such as the housing, gears, pistons, vanes need to be measured to confirm the manufacturing tolerances have been achieved which would include the diameters lengths and concentricity of shafts. Another key parameter during pump inspection is surface finish which is especially critical on meshing parts such as gears and vanes and on sealing faces. Hydraulic pump inspection is the key to longevity of the product.

Optimax supplies a range of solutions for this application including shaft measurement, dimensional measurement, surface finish and gear measurement.

Bruker Alicona G6

system with AR3D

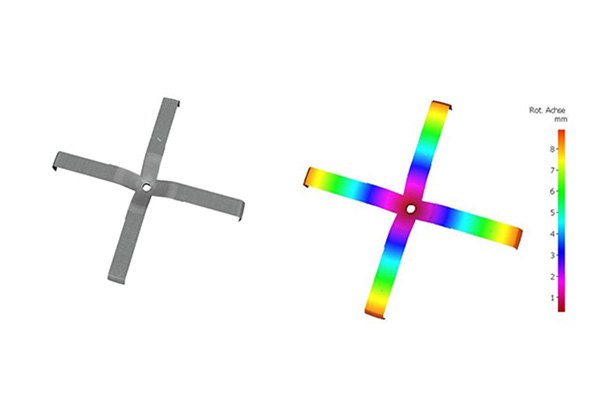

We recommend the InfiniteFocus G6 system fitted with an advanced 3D rotation device. By using IF-AdvancedReal3DRotationUnit, it is possible to measure components around 360° in high resolution, providing an areal analysis of the different required dimensions. This guarantees robust and repeatable quality control in addition to an optimization of manufacturing processes. The Bruker Alicona measurement system also allows for measuring profile and area-based roughness conforming to ISO 4287, 4288, and ISO 25178. User-friendly handling and easy automation using the measurement Inspect measurement module.