Helping a valve disc manufacturer improve their process

One client contacted us to help with their automated production process. As manufactures of metal valve discs for fuel injectors they needed to ensure a fuel-tight seal over the service life of the injector, the outer rim must be complete and free from dents or other damage.

However, detailed examination, potentially using template images or taking measurements, was a time-consuming process and did not provide traceable methodology, printed reports or visual results.

Our solution has revolutionised their output

With the client having a manufacturing rate at m40 parts per minute, the components needed to pass under with a random orientation. In their case, a metal valve was to be placed in an injector must be inspected. The outer rim of the valve should be intact and complete without any breaks, dents, or damage. It must have rotational freedom to be inspected from any position, and ambient light reflections must be ignored. Permitted defects, such as scratches on the surface, must be ignored, along with light reflections on the outer rim. The inspection regime must be fully automated, and inspection must be made at 40ppm. We recommended the Inspekto S70.

The Inspekto S70 autonomous machine vision system

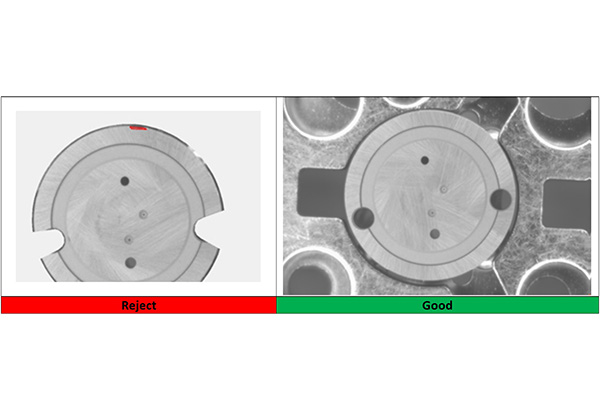

We recommend the Inspekto S70 autonomous machine vision system, which uses a camera and a powerful AI (Artificial Intelligence) image processing system to spot defects whilst minimising false positives. The system is trained using good components and can be configured to ignore product parts that differ by design (such as serial number labels). It is tolerant of orientation and positioning and can scan components placed in the camera’s field of view and on a conveyor belt. Where defects are found, they are identified in red on the displayed or recorded image to facilitate rework.