Thorough inspection processes in CNC machining within the medical device industry is an issue

CNC machining is a widely employed manufacturing method in the medical device industry, where precision is paramount. The intricacy and critical nature of medical device components necessitate a thorough inspection process to identify any imperfections or irregularities that may compromise the functionality or safety of the final product. Many defects can affect the performance of these devices, including Scratches and Scuffs, Tool Marks, Tolerance Violations, Misalignments, Material Defects, Internal Flaws, Foreign Particles, Surface Finish and Burr and Edge quality. A thorough inspection process is essential to detect these potential defects and damages that could compromise the final medical devices’ functionality, safety, and regulatory compliance.

These types of inspection cannot be carried out by eye as the manual optical inspection process in the medical device industry not only contributes to the overall quality control but also aligns with regulatory standards and industry best practices. Incorporating human expertise alongside optical inspection systems ensures that the C NC-machined components meet the stringent requirements of the medical field, contributing to the production of safe and reliable medical devices.

Inspection equipment for maximum effectiveness, minimal operator training

For optical inspection and measurement of medical devices most clients seek user-friendliness and minimal operator training, while maintaining the highest standards in the production of medical devices.

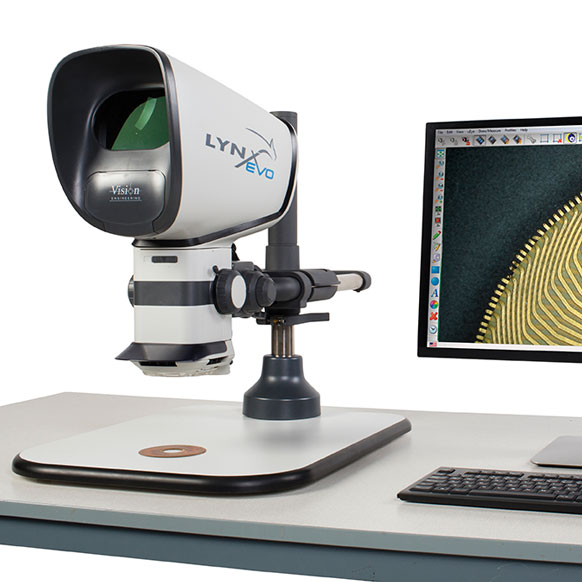

We recommend tools such as the EVO Cam II Digital Microscope time and time again.

Operating at a 50x magnification, it aims to identify imperfections, such as surface scratches, that may elude the naked eye. The EVO Cam II’s exceptional HD image quality and high frame rate eliminate motion blur, ensuring that every detail is captured precisely.

When defects are identified, it’s possible to measure, log, investigate their root causes, and implement necessary process improvements.

Evo Cam 2

If you are seeking a High-Performance Full-HD Digital Microscope, look into the EVO Cam II. It delivers excellent image quality to help uncover hidden details. Optical magnification up to 300x and full auto focus ensure ultra-sharp images at all times. EVO Cam II is optimised for quality control, testing, inspection, and documentation. Leading optical performance makes EVO Cam II a supremely powerful imaging solution with a range of objective lens options to ensure stunning results for any application. Exceptional simplicity minimises training requirements, making EVO Cam II a powerful and flexible tool for multiple users and production environments.