Inspect and measure control valves and valve seats

Control valve inspection and measurement of precision valve seats is critical to ensure the reliable and safe operation of actuators and valves across many industries, from aerospace to automotive. The geometric form, along with dimensional and surface characteristics of these components, are critical for compliance and performance. To accurately measure and inspect control valves, without the risk of damage, requires a non-contact optical 3D measurement device for μm and sub-μm tolerances such as the Infinite Focus G6 from Bruker Alicona.

This Alicona G6 provides, in a single measuring system, the ability to measure, with full traceability, diameter, dimensions, angles, contours and surface finish without risk of physical damage to the valve seat completing the valve inspection checklist according to the API and MSS standards.

Bringing precision to valve inspection and measurement

The Bruker Alicona InfiniteFocus optical 3D surface measurement system has significantly reduced production costs for a manufacturer. The system’s ability to analyse valve sealing and leakage issues related to the geometrical properties of valve seats has allowed for refined designs, leading to a substantial decrease in defect rates. When combined with control electronics, the valve seats’ precise roundness and surface finish are crucial in ensuring accurate and repeatable metering.

The InfiniteFocus system’s ability to measure small deviations in the contour accuracy of valve seats sets it apart from traditional tactile systems. It offers flexibility and accuracy and excels at measuring difficult-to-access geometries and analysing critical surface profiles. The system effectively measures challenging tolerances, in the 1-2 µm range, particularly the small opening angle of the valve seat cone. The focus variation technique enables the measurement of small radii and flanks up to 90°, surpassing tactile and traditional optical methods.

The valve inspection procedure

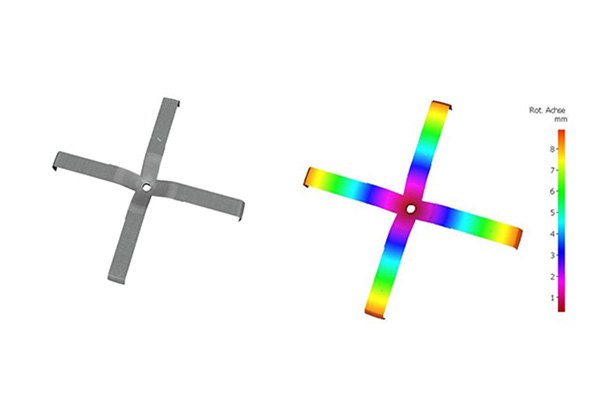

To maximise the service life and prevent one-sided wear on sealing surfaces, concentricity must be accurately assessed to less than 10 µm. The InfiniteFocus system, along with the precise Advanced Real3D Rotation Unit, automates the measurement of a component from multiple directions. The results are merged into a high-precision 3D dataset for comprehensive analysis.

For visual inspection Optimax also supplies a range of Stereo Microscopes and Vision Systems

The InfiniteFocus G6

We recommend the InfiniteFocus G6 system fitted with an advanced 3D rotation device. By using IF-AdvancedReal3DRotationUnit, it is possible to measure components around 360° in high resolution, providing an accurate analysis of the different required dimensions. This guarantees robust and repeatable quality control in addition to an optimization of manufacturing processes. The Bruker Alicona measurement system also allows for measuring profile and area-based roughness conforming to ISO 4287, 4288, and ISO 25178. User-friendly handling and easy automation using the measurement inspection module.