Helping Sheldon Precision measure the finer details

Sheldon Precision is a subcontract manufacturer of precision-turned parts with customers throughout the United Kingdom. Due to their multi-axis capabilities, they can use the latest CNC lathes to deliver complex components with features such as cross-drilling, tapping, and milling, all in a single operation. They supply components to the automotive, defence, and oil and gas industries with a robust ISO 9001 quality system.

Sheldon Precision has used analogue profile projectors for the first article inspection (confirming that the first item of the line is within spec) and in-process inspection. However, they found that there were geometric features that they could not measure, positioning larger parts was difficult, and manually recording readings was prone to error. Their method with manual overlays on a profile projector was no longer accurate enough.

Looking beyond manual overlays

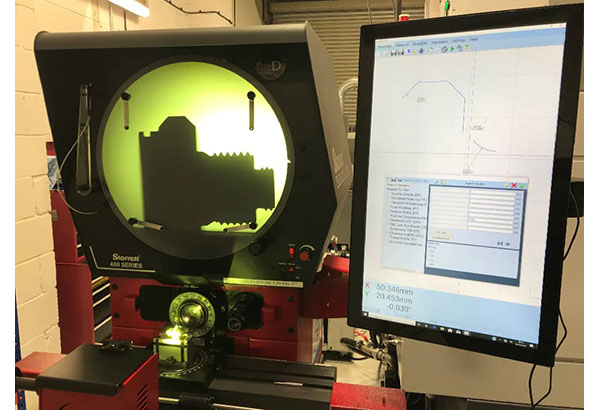

Optimax evaluated the client’s requirements and the instruments they were currently using and proposed a solution built around the Starrett HE400 bench-top profile projector integrated with Optivu Synergy software. Operated by the same shop floor staff, the HE400 has been able to confidently measure the geometric features that previously proved tricky. The dual lenses make it easy to switch between magnifications and enable measurements of larger components. The ring light for surface illumination has meant that the HE400 is replacing a vertical inspection machine.

Starrett HE400 bench-top profile projector integrated with Optivu Synergy software

We recommend the Starrett HE400 bench-top profile projector integrated with Optivu Synergy software. The Synergy software ensures accurate measurement data recording and has automated the calculation of geometric tolerances. Asked why they decided to buy the Starrett HE400 from Optimax, their reply was unequivocal: ‘They had, in my opinion, the most advanced profile projector on the market.’