Supporting orthopedics and traumatology with surgically precise screw measurement

In the very sensitive field of orthopedics and traumatology, damage to the surface of medical devices should be avoided, especially during quality control processes. Optical measurement systems, contactless by definition, represent a solution to prevent damage potentially caused by tactile measurement processes. In addition, optical technologies allow the use of wear-free measuring means, which can be automated even in production and which provide connected and repeatable results.

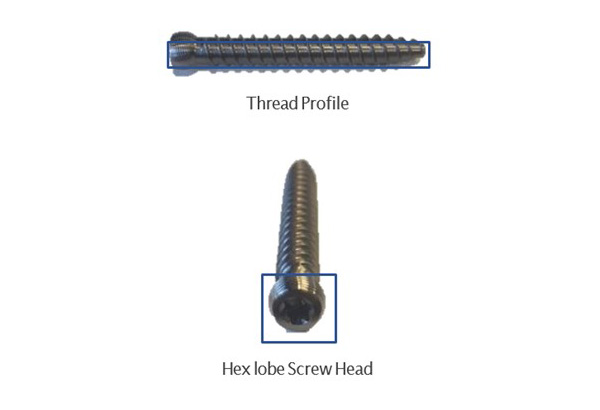

The measurement of osteosynthesis screw heads is a good example of optical dimensional measurement of microgeometries in the biomedical field. The osteosynthesis screw is a medical aid that is placed in the tissues to ensure a stable connection between bones or bone fragments in cases of complex or large fractures. Osteosynthesis screws are the most common fastening aids and can be used alone or in combination with other components (e.g., plates).

In surgical applications, the dimensional accuracy of the screw head is crucial to ensure an accurate connection between the screwdriver and the screw head. This is necessary, on the one hand, to ensure that the head of the screw is not damaged during insertion and, on the other hand, to prevent the screwdriver from slipping and injuring the patient.

Focus Variation Technology offers impeccable precision

For demands of this nature, we believe it is important to find tools that offer easy measurement of multiple areas. Take the Focus Variation technology supplied by Bruker Alicona as an example. It has many powerful features.

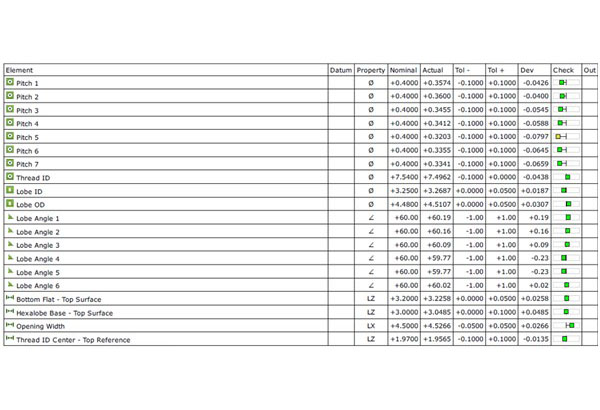

Real3D (360° Acquisition) allows the easy measurement of the ID, OD, tip, and root radius plus surface finish of the thread form. The high depth of focus makes it a straightforward process to measure the internal geometry of the hexagon socket. Not only this, it can measure and compare both the Hex driver and the socket for accurate mating. Both the thread profile and the HexLobe screw head are measured and compared with the designer’s CAD file and the accuracy of the thread profile determines the ease of insertion and the durability of the attachment, whilst the head is required to conform with the profile of the driver. (This ensures that the driver does not slip out in use, preventing damage to the tool or head and in a clinical setting, damage to the operation site.)

Bruker Alicona G6

We recommend the Bruker Alicona G6. In particular, the InfiniteFocus G6 is an accurate, fast, and universal optical 3D measuring instrument designed for optical surface roughness measurement & shape measurement, particularly for smooth and highly polished surfaces. Operating within the µm and sub-µm range, this device provides precise results regardless of component size, material, geometry, weight, or surface finish, all accomplished with only one optical sensor. The Infinite Focus device can be used to scan the drive tool and report on the compatibility of the fit, a true asset.