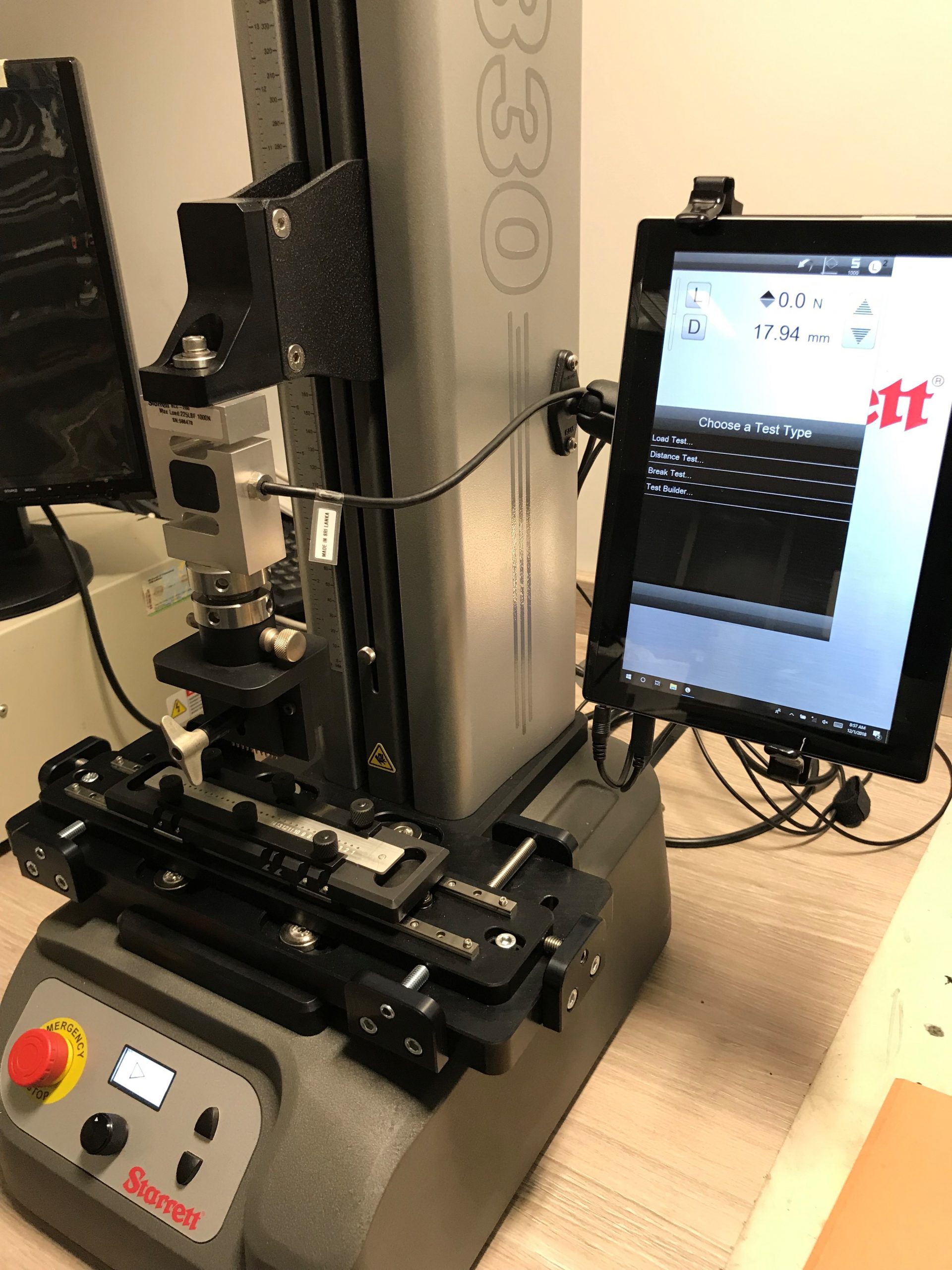

Brandauer is a leading producer of precision stamped parts. Founded in Birmingham over 150 years ago, this family run enterprise has real manufacturing pedigree, recently winning a Queen’s Award for international trade. Committed to leading edge innovation, they are the only UK supplier of the EloPin press-fit, developed by TBS Sorig. Suited for safety critical applications, the versatile, automated, Starrett L2 force measurement system (FMS) is relied upon for quality control in EloPin production.

The desire to eliminate soldering operations from assembly in the electronics sector has led to an increased reliance on press-fit solutions. The robustness of traditional press-fit solutions is however, limited. Repeated use places mechanical stress on the PCB and can cause it to become deformed. Brandauer offers a stand out solution as the only UK supplier of the EloPin press-fit, a solder-free, gas-tight interconnect with requirements for extraction and insertion forces. Although easy to insert, the EloPin press-fit has a high pull out force and a design that limits the issue of “tin whiskers” that occur, when the PCB’s are flow soldered. The fast growing electrical car industry and trend towards smaller, safer cars leads to a demand for robust, affordable and miniaturized electrical interconnection components. The EloPin meets these demands, as a cost-effective easy implementation solution, resistant to temperatures from – 40°C to 150°C and available as small as 0.6mm in diameter.

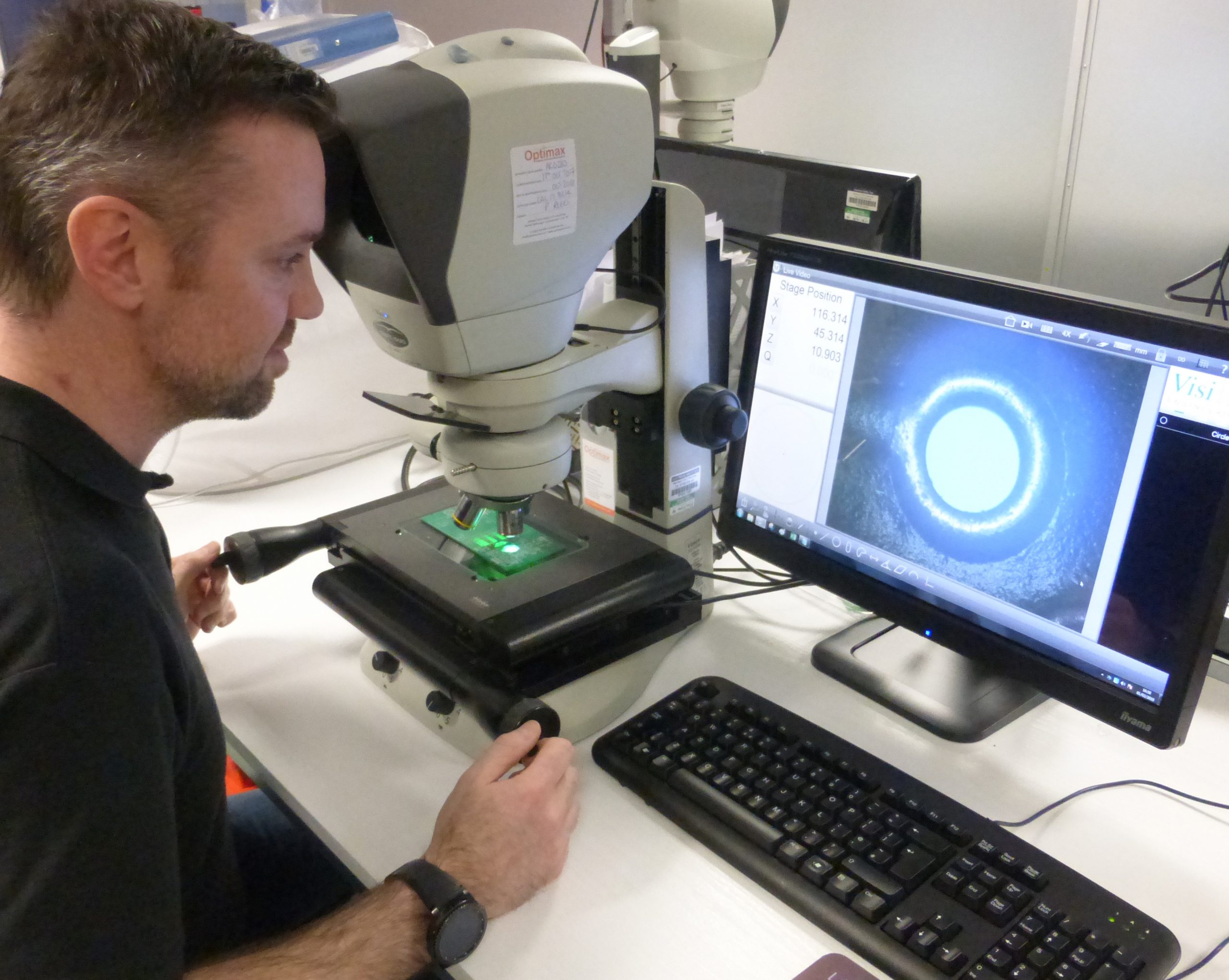

The EloPin press-fit poses a significant measurement challenge. The size of the pins and the pin-hole alignment during insertion, requires precise alignment and complete automation when implemented into a production environment. The insertion and extraction force is measured using a motorised mechanical frame, with load cell and controlling software attached. Starrett manufacture many different variants and in this case the FMS frame with L2 software matched the strict drawing parameters. Optimax designed and built a specialised jig for the Starrett L2 FMS, allowing various sizes of EloPin to be loaded and the measurements completed without out operator alignment. It was this comprehensive, end-to-end solution that attracted Brandauer to Optimax:

“We were not just ordering a generic device, but required a purpose built jig – which would have been difficult and time consuming for us to make ourselves. Optimax also provided full support, training and programming, they even sourced the test PCBs for us. They really offered a complete solution to our application.” – Adam Burgoyne, New Product Introduction and Quality

Safety parameter programs were included within the Optimax turnkey jig. If the pins are misloaded onto the jig, or the pin is bent and misses the hole, the increased insertion force causes the machine to stop. The robust FMS L2 Starrett force machine is therefore able to run throughout the day, testing every reel of 20,000 pins stamped. By simply changing the jig, Brandauer are also able to measure a second, American press-fit solution and a range of products for their Chinese clients.

The robustness and versatility of the L2 Starrett has had significant impact on cycle times as well as satisfying Brandauer’s commitment to the highest level of quality control. The device is intuitive to use and fully programable, allowing for use by staff not trained in inspection. An attractive feature for Brandauer who hold as a core operating principle that press shop operatives share ownership for the product quality coming off the press tools.

“Efficiency of the production process has definitely improved. The device is versatile, cost effective and intuitive to use – load the part and press a button.”