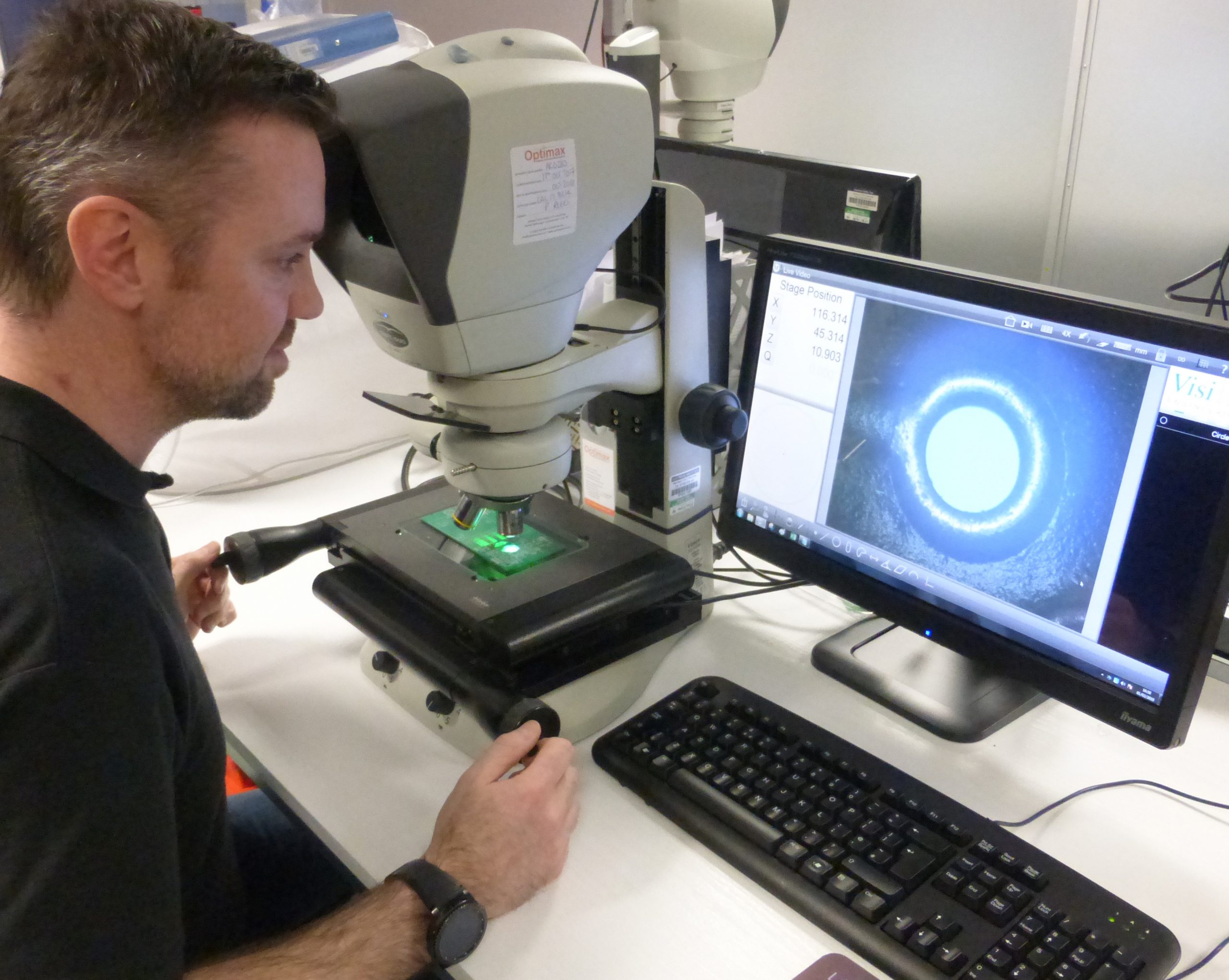

Cell membrane re-engineering is a powerful frontier in biomedical innovation. Researchers at Bristol University are facilitating the improved therapeutic performance of cells, by modifying them to take on new functionalities. Essential to this groundbreaking work is the Starrett FMS-500-L2 supplied in the UK by Optimax IIM ltd.

Ioannis Zampetakis, a lead researcher on this project, explains that they are examining how human stem cells can be re-engineered to be self-supporting, robust and display a novel thrombin construct. In the case of injury, thrombin converts fibrogen into fibrin, which forms a blood clot, to prevent excessive bleeding. These re-engineered cells could therefore be injected into an injury site or used in organ transplant. The modification is achieved by the addition of human stem cells to a ‘biocompatible and biodegradable scaffold’ (Deller et al. 2019) in a medium. The choice of medium effects the mechanical properties of these cells, which can be quantified through precise, repeatable measurement by the FMS-500-L2.

Through compressive testing researchers identify the properties of these differentiated cells and can determine whether they will withstand the mechanical pressure of the human body.The FMS-500-L2 has the versatility to meet the precise requirements of the researchers’ specific application. Given the size and rigidity of the scaffolds, with 8ml 1-2mm diameter, a device was needed to meet the challenge of measuring a low force at high resolution. The 5-20N load cell was advised by Optimax, as it is used commonly for testing in this environment.

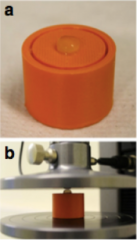

‘Each sample was mounted onto a PLA stage and subjected to destructive compression testing at a rate of 1 mm per min.’ (Deller et al. 2019) Figures a&b show ‘Compression testing of 3D hMSC fibrin hydrogel constructs. Images of a 3D hMSC fibrin hydrogel construct (Dia. = 8.0 mm; depth ∼4.2 mm; ≈4 × 106 cells) before (a) and during (b) unconfined compression testing.’ (Deller et al. 2019)

The compact device size and small operating tablet are essential to meet the size regulations for research facilities working with human stem cells. Ioannis, explains that they have seen excellent usability: ‘the device is very reliable with a 1 – 1% error.’ Used as the baseline for measurement of mechanical rigidity, every researcher must be able to operate the machine, the programming capacity and intuitive controls of the FMS-500-L2 have therefore been transformative.

‘The Starrett Force measurement machine is interactive and very easy to use. By just pressing two buttons we can do the analysis, retrieve the data we want and export it. Optimax provided us with the product demonstration, application advice, specified the correct load cell and calibrated the device, all at excellent value.’

References:

Robert C. Deller et al. 2019. Artificial cell membrane binding thrombin constructs drive in situ fibrin hydrogel formation. Nature communications, vol. 10, pp. 1-10.