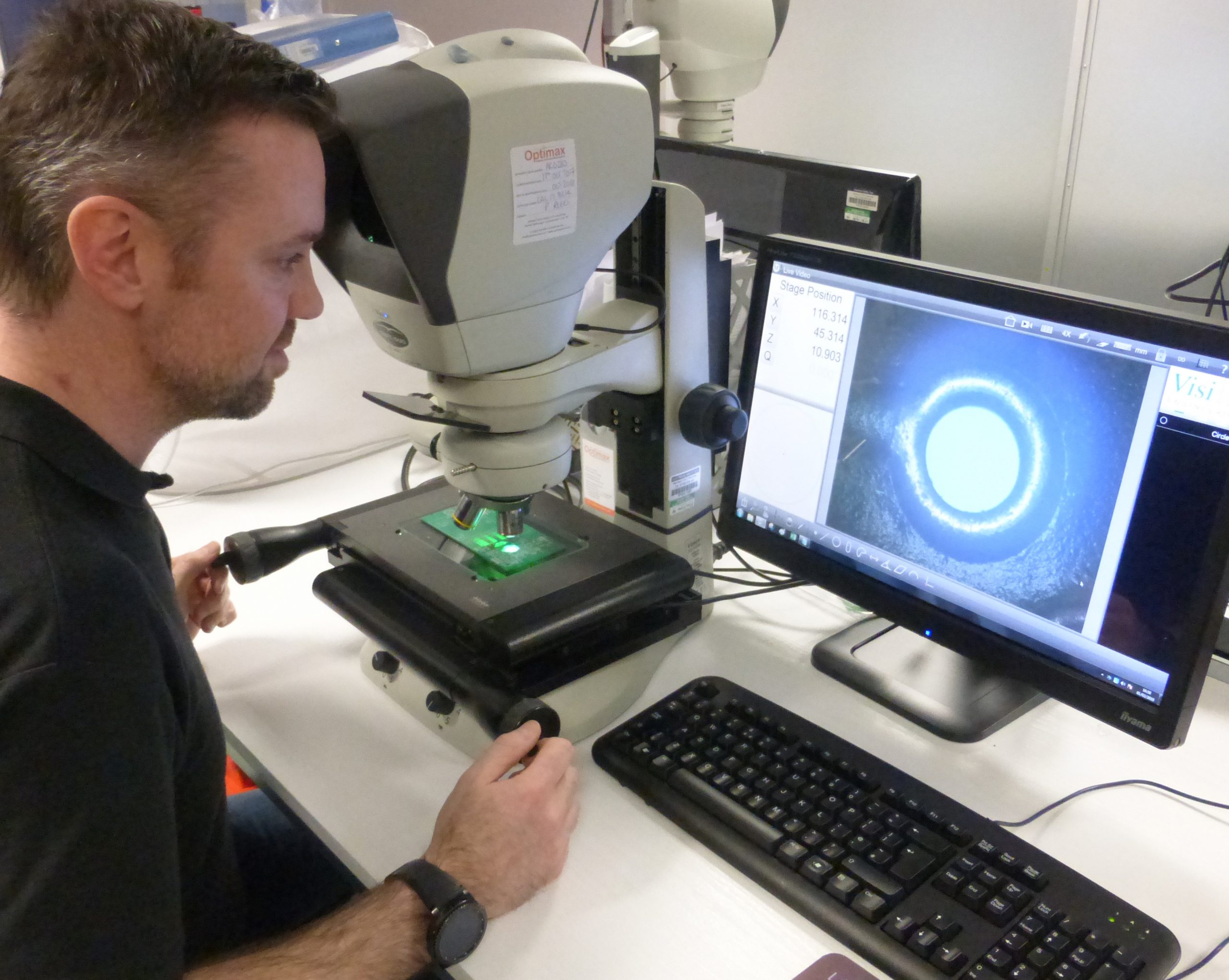

The modernisation of vehicles has brought new challenges for automotive manufacturers with the shift from hydraulic to electric power assistance requiring new, specialised inspection equipment. Re-Go Autoparts, the high-quality remanufacturer of steering components, invested in a complete solution for high precision electrical rework and circuit board inspection – Vision Engineering’s Evo Cam with articulated arm mount.

Re-Go Autoparts are committed to delivering the highest quality re-engineered steering components with a service life equal to that which the part had before it needed an overhaul. Their requirements for the high-magnification view of electrical components poses a significant inspection challenge, as these small parts are mounted onto heavy and awkward workpieces. Having received a complete measurement solution from Optimaxpreviously, Re-Go Autoparts were confident in their purchase of the Evo Cam with articulated arm mount. In interview, Gary Martin explained that:

‘We saw that the Evo Cam was the most suitable device – really ticking all the boxes. Most competitor equipment is fixed to a stage which wouldn’t allow us to fit our workpieces below it. With such a complex process you must have a good view of the components, so the flexibility and manoeuvrability of the articulated arm mount is crucial. The Evo Cam’s overlay grids also offer useful reference for scale, which is ample for this application.’

The large working distance between camera and workpiece and the moveable display, further ensures the maintenance of a comfortable working position for the operator and excellent hand-eye coordination. Gary explained that reducing worker fatigue was a crucial motivation in the purchase of this ergonomic solution:

‘You have the ability to put your hands under the camera so you have space to work, use tools, tweezers and soldering work. It becomes natural and easy to use in a short time. Let’s face it, surgeons use this type of set up now as routine in operations – enough said.’

The video camera also facilitates digital zooming in addition to the optical zoom. The image capture facility also allows Re-Go Autoparts to easily generate reports for customers to explain what is damaged, and for suppliers to discuss needed parts. This improved traceability also supports essential research and development work.