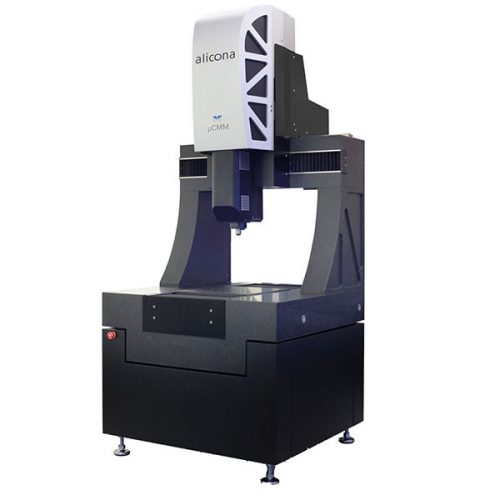

Alicona EdgeMaster X

Fully automatic measurement of cutting tool edges in production

The EdgeMaster series of Alicona products are used for automatic high-resolution measurement of tool cutting edges in production. Designed for the measurement of inserts, round tools or hobs on the shop floor or measurement room.

Using the focus variation technique, users measure radii >2μm as well as rake, wedge and clearance angle of tools including both waterfall and trumpet. Traceable and repeatable results are provided unaffected by vibration, variation in temperature and ambient light. The high vertical resolution also enables traceable roughness measurement on the rake face. Users can also measure differential and wear parameters according to ISO 8688, such as flank wear. The software allows fully automatic measurement once a program has been created.

The Alicona EdgeMasterX’s expansion from 3 to 5 axes with a high-precision tilting and rotating axes allows measurements of tool geometries that are otherwise difficult to access.

Application includes manufacturing, tool sharpening and tool manufacturers.

The measuring and inspection of cutting tools is essential across all markets, but especially in manufacturing, tool sharpening and tool manufacturers. With even the smallest discrepancies causing havoc on production lines, fast, flexible and accurate non-contact metrology is the backbone of the operation. The EdgeMasterX has it all.

Specifications

- Verify multiple edges in one measurement run

- Optical, high-resolution tool measurement in production

- An extension of the EdgeMaster

- Measurement of different edge parameters on different positions of a tool

- Measurement of user-defined parameters on tools of a batch

- In combination with a rotation unit, chamfered cutting edges detected in one measuring run

- Non-contact, optical, three-dimensional, based at Focus-Variation

- Positioning volume (X x Y x Z): RL objectives: mot.: 50 mm x 50 mm x 155 mm (Z: 25 mm mot., 130 mm man.) = 387500 mm³

- SXRL/AXRL objectives: mot.: 50 mm x 50 mm x 120 mm (Z: 25 mm mot., 95 mm man.) = 300000 mm³