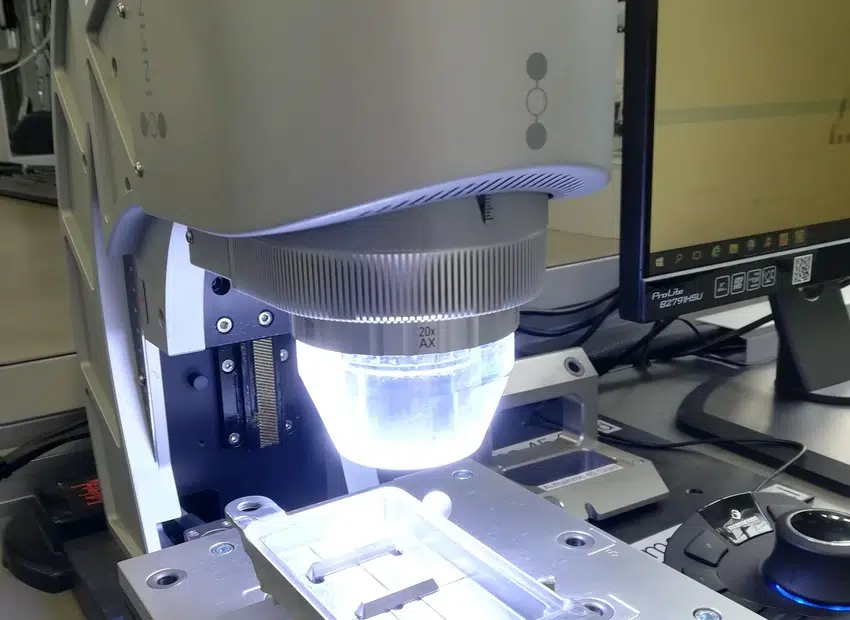

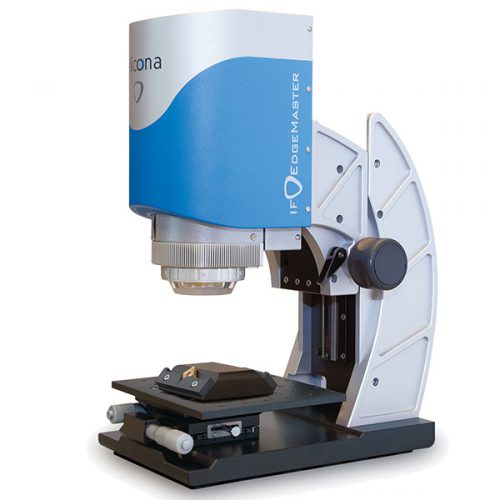

Alicona InfiniteFocus SL

The ultimate non-contact metrology device for surface characterisation and surface roughness

The InfiniteFocusSL is a cost-efficient optical 3D measuring device for simple, fast, and traceable measurement of shape and surface finish on micro structured surfaces designed for use on the shop floor for multiple users.

Using focus variation, it combines the small depth of focus of an optical system with vertical scanning to provide topographical and colour information from the variation of focus. This creates a 3D model on which form, and roughness measurements are made in the μm and sub-μm range.

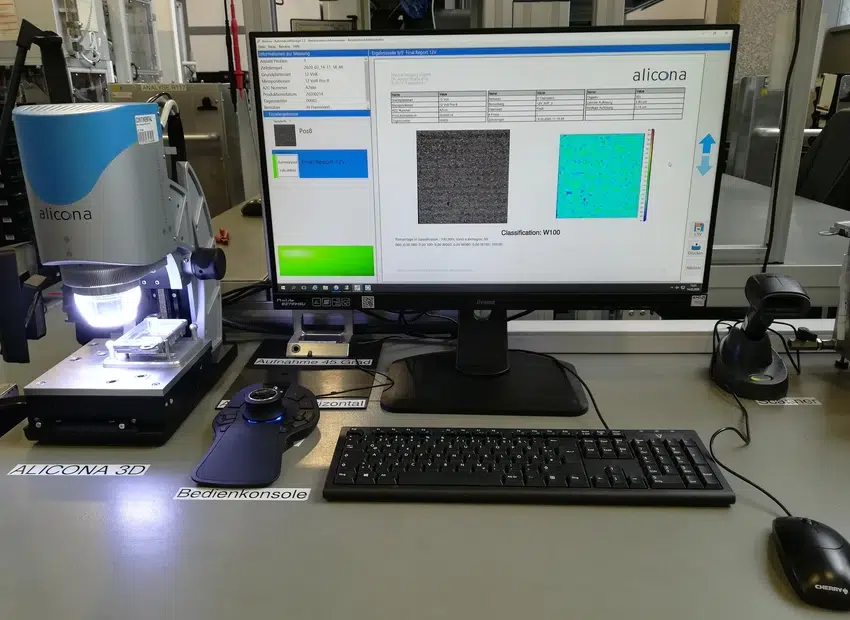

The software used with the Alicona InfiniteFocus SL allows the measurement of form and roughness, angles, distances, radii, volume analysis, contour measurements and difference measurements.

The expansion from 3 to 5 with a high-precision tilting and rotating axes allows measurements of geometries that are otherwise difficult or impossible to access.

Application areas commonly in use include Precision Manufacturing, Cutting Tools, Aerospace, Automotive, Medical, Electroforming and Electronics , both on the shop floor and in the measurement room

Specifications

Case Study

3D measurement technology & AI ensure reliable powertrain technologies: Detection of smallest differences in roughness

For the implementation of a new laser cleaning process, Vitesco Technologies, formerly Continental Division Powertrain was looking for a measuring device to monitor the performance and quality of laser processing in series production. The automotive supplier found it in a Bruker Alicona 3D measuring system. In addition to the 3D topography measurement, this offers a new classification software. Based on AI, the software automatically detects OK and not OK surfaces.