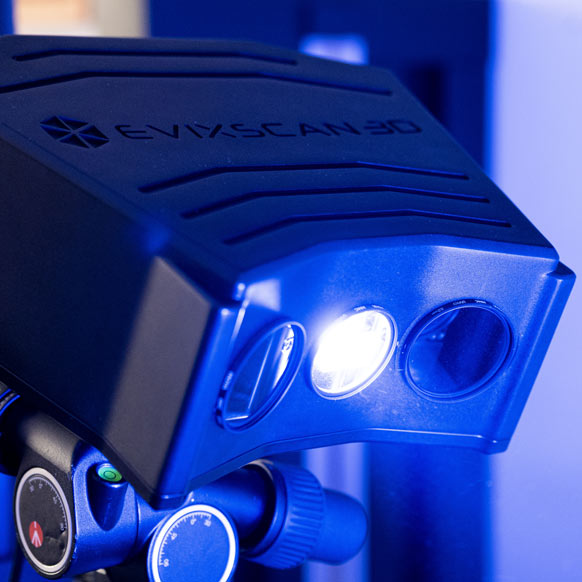

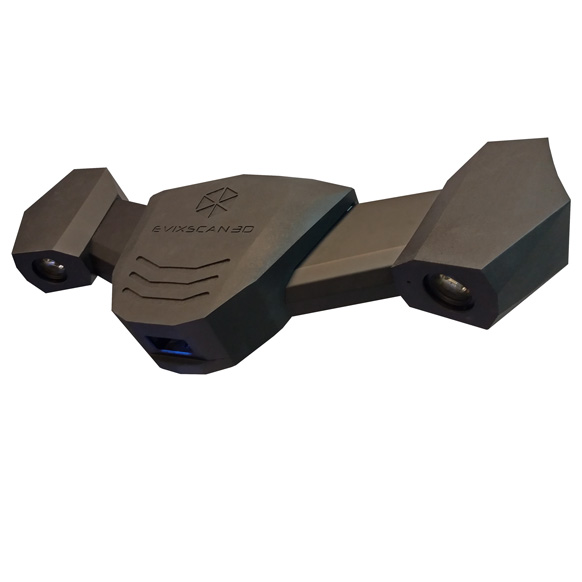

EviXscan Quadro+

Unmatched precision for industrial metrology & quality control

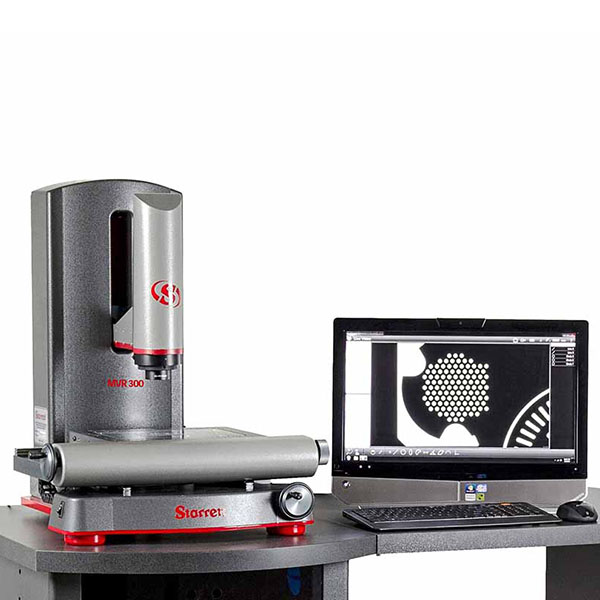

The eviXscan Quadro+ is an industrial structured light 3D Scanner designed for capturing intricate details on components in high resolution. It can be used for precision metrology, quality control, reverse engineering and rapid prototyping application and is unique in having dual scanning ranges.

Utilising a blue LED light source and 4 high resolution cameras (two 12 Mpix for the inner range and two 9 Mpix for the outer range) to capture highly accurate 3D data. The inner range, designed for smaller, more intricate objects, offers a point density of 351 pts/mm² and the outer range, for larger objects, provides a point density of 88 pts/mm² allowing high resolution measurement.

The eviXscan Quadro+ delivers exceptional measurement accuracy, validated by VDI/VDE 2634 Part 2 standards, with precision down to 0.007 mm

Despite its unparalleled precision it can scan an object in as little as 1.2 seconds with an inner range measuring approximately 220 x 160 x 90 mm and large objects with an outer range of roughly 450 x 225 x 180 mm.

Designed for the rigours of the production environment and provided with he intuitive eviXscan 3D Suite software, which provides powerful tools for point cloud processing, mesh editing, and data export to common formats like STL, OBJ, and PLY. This software also allows for the seamless combination of scan data from both inner and outer ranges, providing a complete 3D representation of an object

The eviXscan Quadro plus many uses in many industries including Automotive, Aerospace and Defence, Heavy Industry and Machinery Manufacturing, Electronics & Consumer Goods, Tooling, Molds, and Dies, Research & Development / Academia and medical.

Specifications

- True 3D surface model data collection

- Whole surface and all geometric element measurements in a single operation

- Surface preparation not normally required

- Easy transfer of data between different software packages

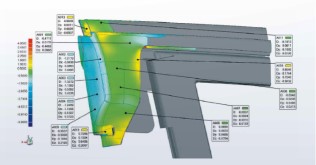

- Extract traditional GD&T parameters or reverse engineer fully automatically

- Designed for the production environment

- Two scanning ranges in one device

- Easy to change scanning range with no need for re-calibration

- High point density for maximum geometry capture

- High quality pattern display with 1080 Mpix Blue LED projector

- Cobot and robot integration

- EviXscan 3D Suite 2.8 software as standard for optimum speed and quality

- Minimum scanned object size 40-50mm

- Maximum scanned object size 1000-1500mm

- Inner Range:

- Measuring range 220 x160 x 90mm

- Camera resolution 9 Mpix

- Point density 351 pts/mm2

- Outer Range:

- Measuring range 450 x 225 x180mm

- Camera resolution 12 Mpix

- Point density 88 pts/mm2

- Automatic execution of multiple scanning scenarios

- Full repeatablility of scanning process without the need for user intervention

- Ability to use QR code readers

- Suitable for 24/7 operation in production environment

Case Study

Cooper Standard Automotive is a leading supplier of plastic and rubber components for the automotive industry.

Learn how they have successfully integrated EviXscan 3D scanners into their production processes for Quality Control, Reverse Engineering and Rapid Prototyping, shortening production time and lowering costs.