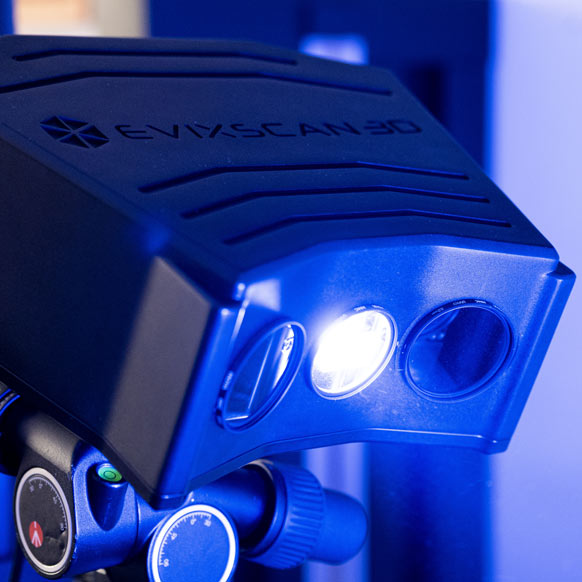

EviXscan WideRange 65

Automate your quality inspection with the eviXscan WideRange 65

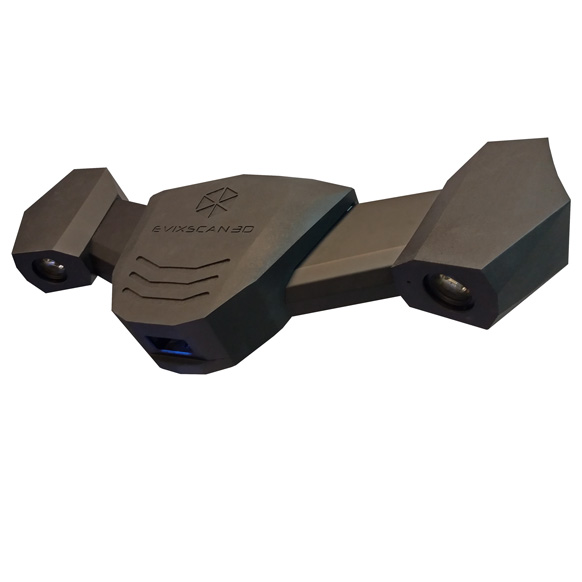

The eviXscan WideRange65 is an industrial structured light 3D scanner used in non-contact quality control of large workpieces. Designed for scanning medium sized objects with a more focussed range it can be easily integrated into production for automation offering an economic cost-performance balance. It uses a blue LED light source and an 8.9 Mpix high-resolution camera for accurate 3D data. It produces dense data clouds with a point density of 54 pts/mm² allowing for detailed and verifiable scans.

The WideRange65 delivers measurement accuracy down to 0.009 mm. It scans objects quickly, in as little as 1.2 seconds, and can scan objects in the 300mm – 2000mm range with a field of view of 575 x 290 x 240mm.

Designed for production the WideRange65 can be integrated into a manufacturing line or mounted on a cobot providing a strong value robust solution. It comes with the eviXscan 3D Suite software providing tools for point cloud processing, mesh editing, and data export (STL, OBJ, PLY allowing for the extraction of GD&T parameters or Reverse Engineering. The WideRange65 is perfectly suited for industries that demand precise analysis of large-scale objects—such as automotive components, aerospace parts, and industrial machinery.

Specifications

- True 3D surface model data collection

- Whole surface and all geometric element measurements in a single operation

- Surface preparation not normally required

- Easy transfer of data between different software packages

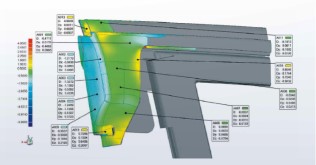

- Extract traditional GD&T parameters or reverse engineer fully automatically

- Designed for the production environment

- High acuracy and fast scanning time

- Easy to change scanning range with no need for re-calibration

- High point density for maximum geometry capture

- High quality pattern display with 1080 Mpix Blue LED projector

- Cobot and robot integration

- EviXscan 3D Suite 2.8 software as standard for optimum speed and quality

- Minimum scanned object size 300mm

- Maximum scanned object size 1200-2000mm

- Measuring range 575 x290 x 240mm

- Camera resolution 9 Mpix

- Point density 54 pts/mm2

Case Study

Cooper Standard Automotive is a leading supplier of plastic and rubber components for the automotive industry.

Learn how they have successfully integrated EviXscan 3D scanners into their production processes for Quality Control, Reverse Engineering and Rapid Prototyping, shortening production time and lowering costs.