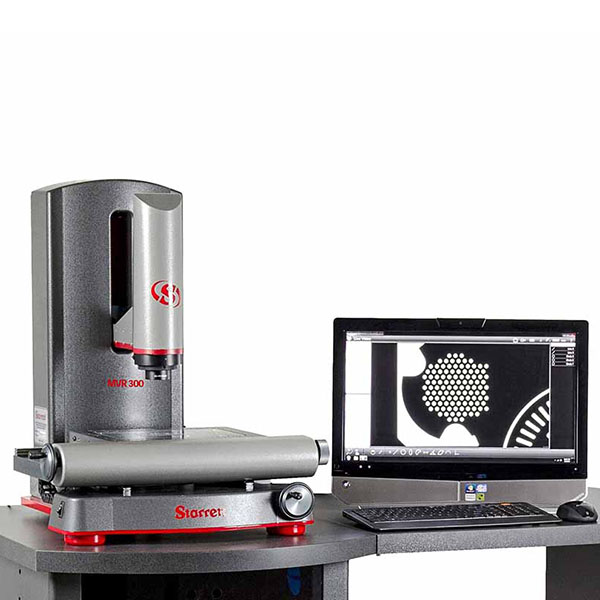

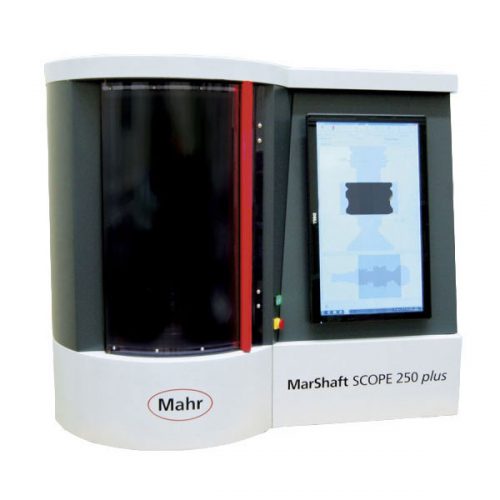

Mahr MarShaft Scope 600 / 850 plus 3D

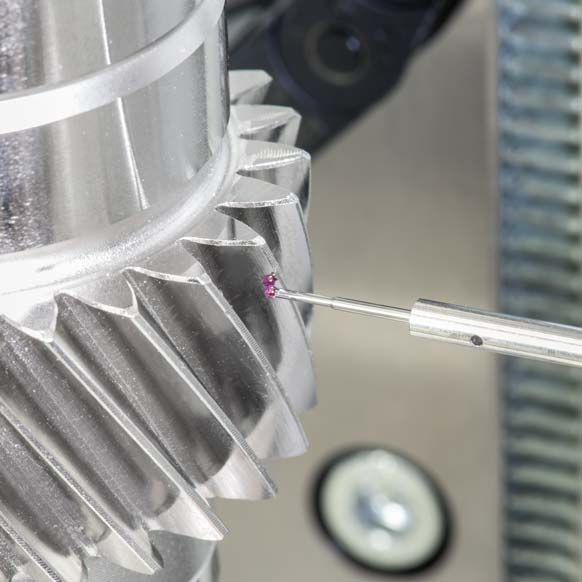

3D shaft and gear measurement with optical and tactile sensors

Unlike other shaft measurement systems, the MarShaft 600/750 plus 3D uses both optical sensors and tactile measurement probes to deliver high quality 3D results. Accurate and repeatable measurements are possible for almost all rotationally symmetrical workpieces including, camshafts including the cam shaft angle, cylindrical gears shafts, contour elements, feather key grooves and blind holes and gears.

Ideal for use in the automotive and aerospace industries where there is a need to accurately measure gear shafts and camshafts, the MarShaft Scope 600/750 offers an automated measurement solution . Its short measuring times and 100% 3D functionality make it highly desirable in most precision manufacturing applications.

Visit our laboratory for a full product demo.

Specifications

-

Complete measurement of:

- camshafts including the cam angle

- the gears on cylindrical gears

- contour elements

- feather key grooves

- blind holes

- Complete measurement of camshafts and gear shafts

- Short measuring times

- Highly accurate form and position measurement

- 100% 3D functionality

- MarShaft professional software

- Measuring range length (Z) 600mm or 850mm

- Measuring range diameter (X) 120mm

- Length/diameter resolution 0.01 to 0.0001mm

- Angle resolution 0.01' to 0.0001'

- Length error limit (Z) (um) (2+L/125) L in mm (at 20'C +- 1'C on reference standard)

- Diameter error limit (X) (um) (1.0+L/125) L in mm (at 20'C +- 1'C on reference standard)