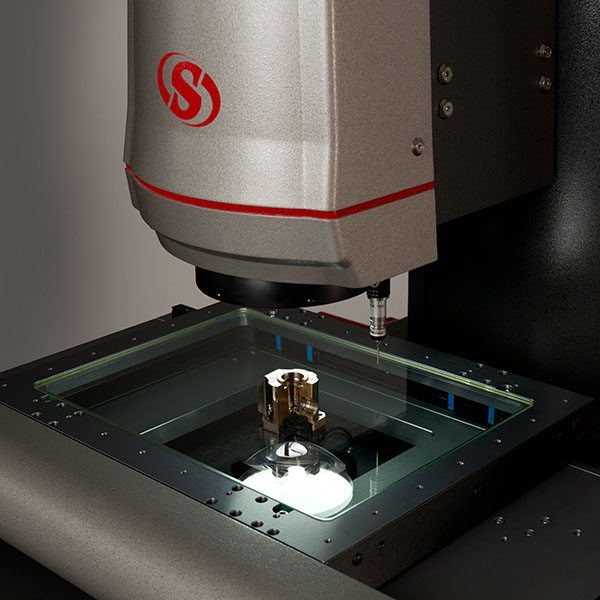

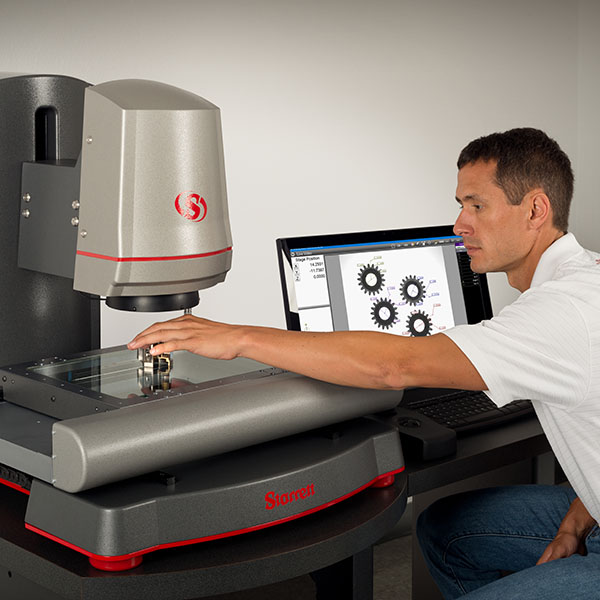

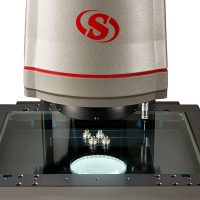

Starrett AVR-FOV 0.14

FOV CNC benchtop vision system with direct CAD comparison

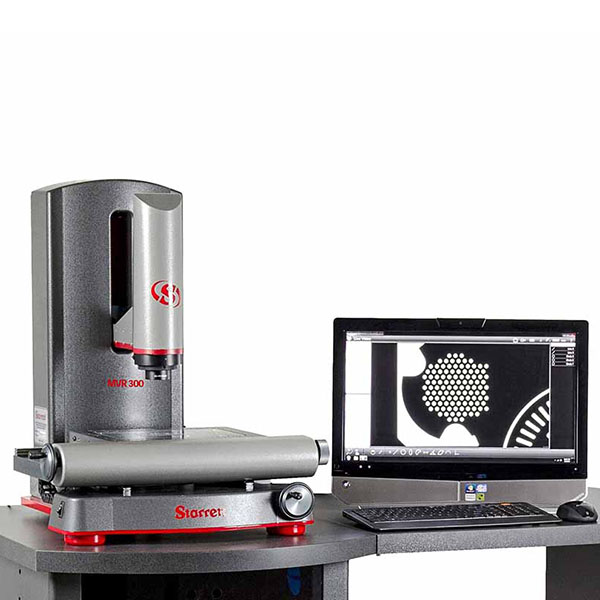

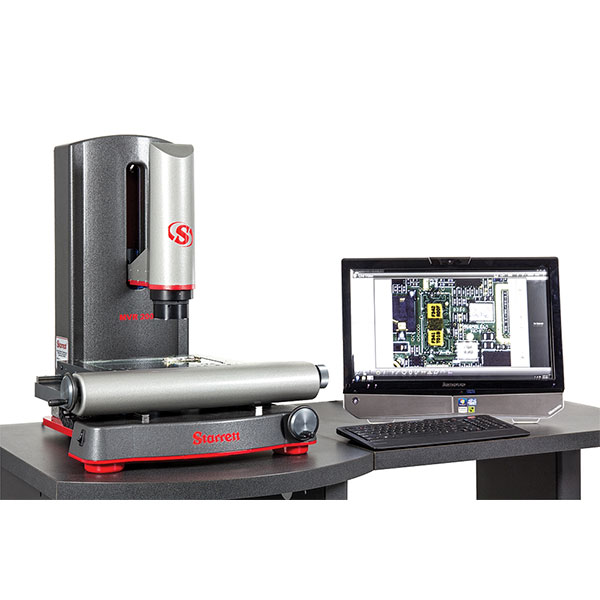

AVR-FOV Automatic Vision Metrology Systems are the next evolution to the Starrett bench top vision metrology family. They are ideal for repetitive measurements and automatic comparison to CAD files providing automated measurement for quicker, more accurate results, while direct CAD comparisons make quality control exceptionally efficient.

Systems are available with a large 60mm FOV-dedicated 0.14X telecentric lense for micron-level resolution and accurate FOV imaging and measurement without need for complicated calculations.

The operator interface is the MetLogix™ M3 software that displays a live video image of the part plus geometry tools and digital readings. M3 software capabilities also include 3-axis measurements and 2D geometric constructs (points, lines, angles, rectangles, slots, blobs). Systems are also touch probe compatible

These benchtop vision systems are operator-led, enhancing repetitive inspection routines with easy import and export features. Get in touch with Optimax to understand the full capabilities of the AVR-FOV 1.4 with a personal laboratory demonstration.

Specifications

Case Study

“The AVR300 is transformative – optimising processes and cutting down inspection cycle-times. The AVR300 is everything we needed in one machine. It’s invaluable for ensuring part conformance to meet sector requirements.” – Quality Manager, Jonathan Fraser