Starrett AVX550

CNC video-based measurement system for quality control

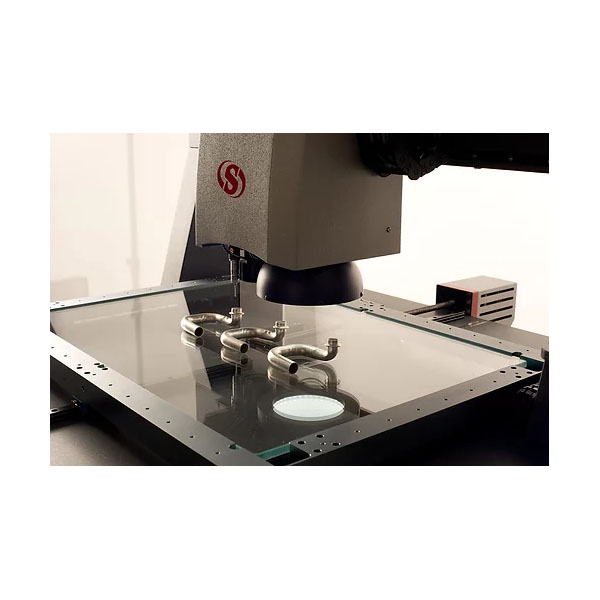

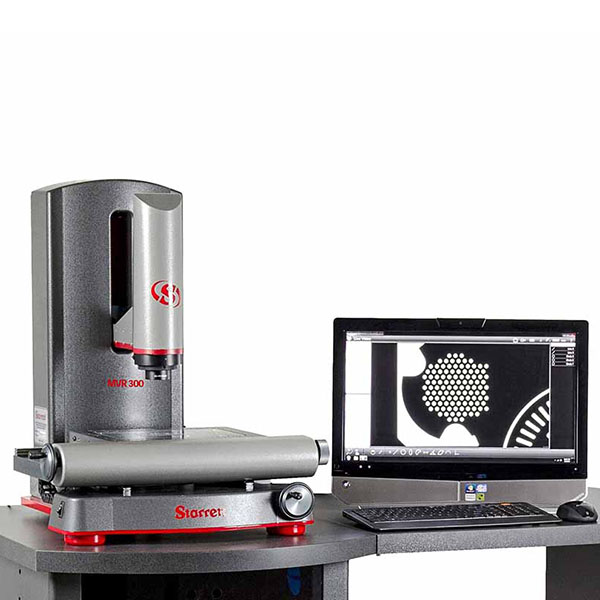

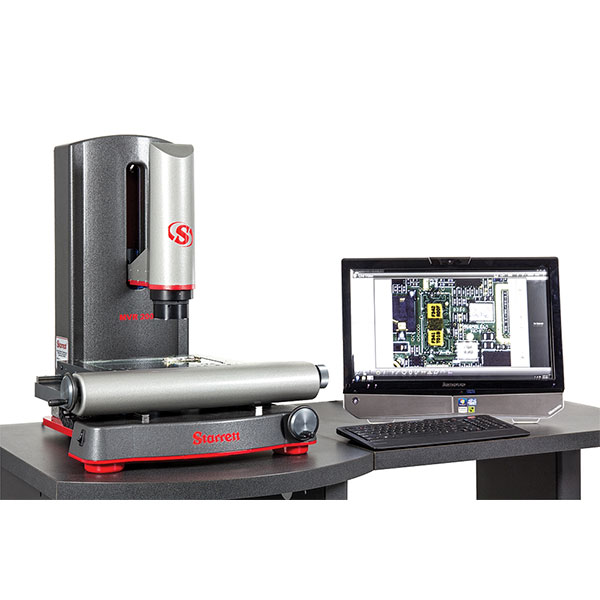

The Starrett AVX550 is a versatile, high-precision CNC automatic vision dimensional metrology system designed for inspecting large, complex parts in quality control (QC) labs, research, engineering, and manufacturing environments. It combines advanced optical imaging with touch probe capabilities, making it suitable for a wide range of applications, including aerospace, automotive, and medical device manufacturing.

The AVX550 provides large format measurements with X-Y-Z travel of 550mm x 400mm x 250mm, accommodating sizable components with intricate features. There are a huge range of options to choose from when configuring an AVX550, from dual camera inputs and ergonomic workstation to quadrant LED surface illumination and auxiliary lens options. AVX models utilize linear guide X-Y transport for ultra-smooth, high speed positioning and are driven by precision lead screws and servo motors.

The intuitive MetLogix™ M3 software supports video edge detection, CAD file import/export and automatic part recognition, streamlining the measurement and inspection process.

Specifications

- Type of system: Floor standing

- Orientation: Vertical

| AVX550 | |

| X-Y-Z Travel (mm) | 550 x 400 x 250 |

| Z axis Measuring | Standard |

| X-Y Accuracy (µm) | E2 = 2.5µm +5L/1000 |

| Z Accuracy (µm) | E1 = 2.5µm +5L/1000 |

| Scale Resolution | 0.1µm |

| Zoom Optics | 12:1 |

- Choice of dual camera inputs

- Dedicated 12:1 CNC zoom optics

- 0.5x, 1.5x and 2.0x auxiliary lenses for zoom optics

- Quadrant LED surface illumination

- DXF/FOV option for automatic comparison to CAD designs

- Adjustable ergonomic workstation including a compact control panel and standard keyboard

- CNC rotary axis fixture

- Renishaw touch probe kit

- Renishaw probe changing rack

- Calibration standards

- Part fixtures and work holding devices