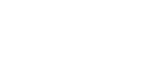

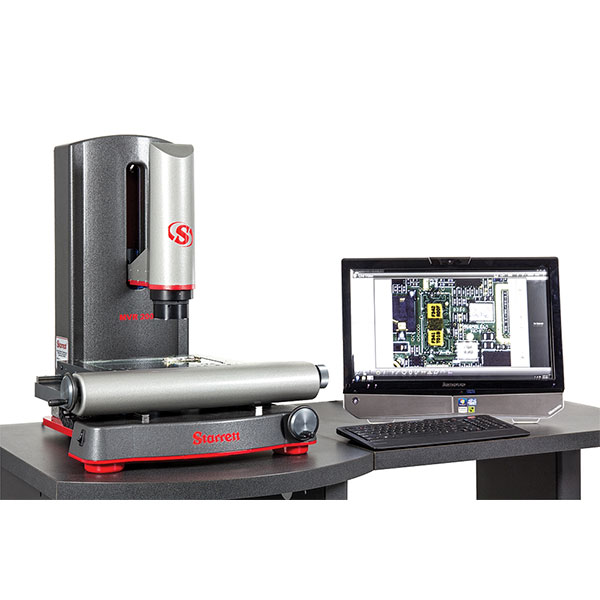

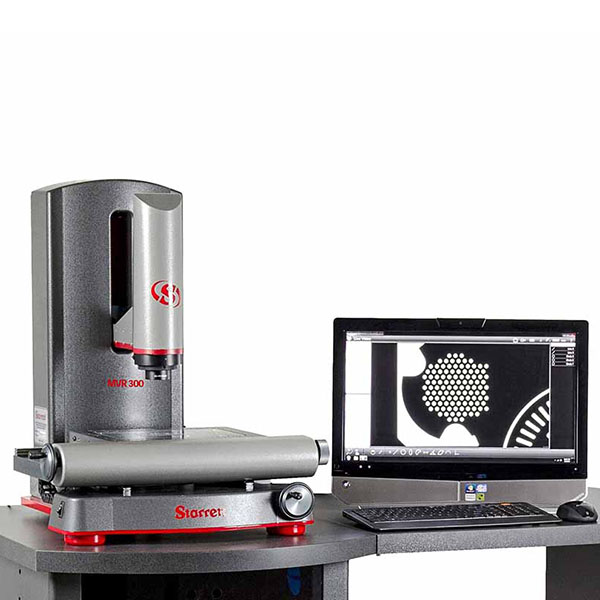

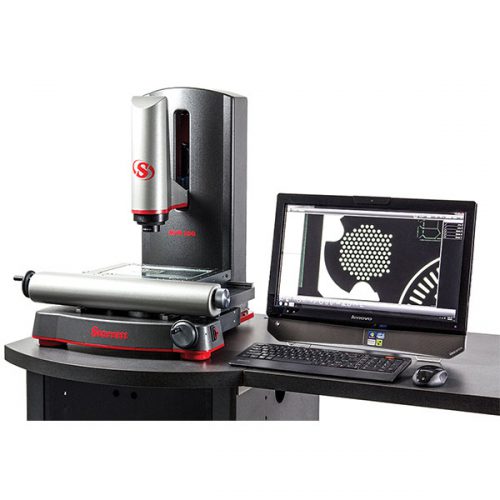

Starrett MVR200

Manual vision system for quick and repeatable measurement and reporting

The Starrett MVR 200 is a manual vision system featuring factory-fitted manual zoom optics compared to the MVR200 FOV which features a quick-change bayonet lens mount for interchangeable lenses. Both models have a maximum field-of-view of 24mm and are capable of measuring parts with a length of up to 200mm.

The MVR200 is a basic model offering a cost-efficient yet highly reliable solution for those in need of a compact benchtop manual vision system. Quick measurements for quality control can be generated by users thanks to the user-friendly MetLogix™ M3 operator interface. The software for the manual vision system displays a live video image of the part plus geometry tools and digital readings.

The image of the part can be resized using zoom and measurements can be taken by simply touching a feature on the touch-screen monitor. MVR hardware features include a granite base for maximum stability, precision linear guides for smooth, accurate stage motion and a motorised Z-axis with variable speed control.

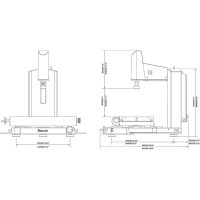

Specifications

- Bench top system with Granite Base

- Manual X-Y stage operation via hand wheels

- Motorized Z-axis positioning with variable speed control

- Metlogix M3 Software with video edge detection

- 24" Touchscreen PC Display

- Zoom Optics - 6.5:1 as standard

- Digital Video Camera: 1.3 MP colour (2.0 MP with telecentric)

- LED surface ring and transmitted illumination (optional coaxial)

Have any questions? Contact us, we would love to hear from you.

- Type of system: Bench-Top

- Orientation: Vertical

- Measurement resolution: up to 3μm

- Measurement accuracy: up to ±3μm

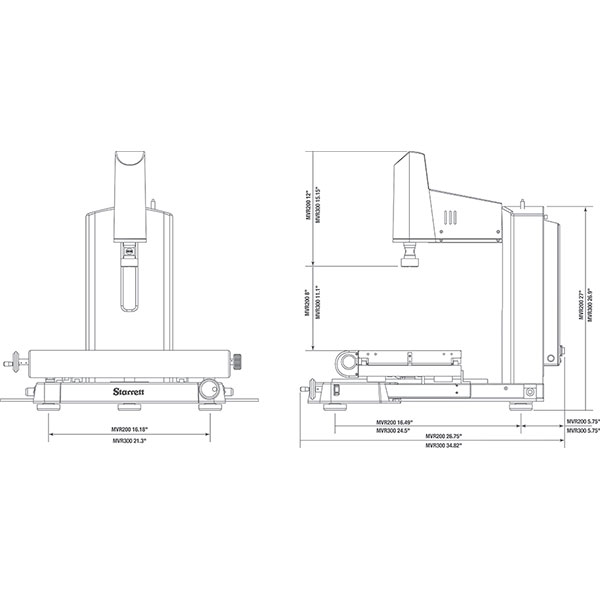

| MVR 200 | |

| X-Y-Z Travel (mm) | 200 x 100 x 200 |

| Z axis Measuring | Optional |

| X-Y Accuracy (µm) | E2 = 1.9µm +5L/1000 |

| Z Accuracy (µm) | E1 = 2.5µm +5L/1000 |

| Scale Resolution | 0.5µm |

| Zoom Optics | 6.5:1 |

- DXF / Field of View (FOV) option for automatic comparison to CAD files

- Interchangeable telecentric and zoom lenses

- Part fixtures and work holding devices

- Auxilliary lenses: 0.5x , 1.5x and 2.0x

- Interchangeable telecentric lens magnifications including - 0.3x, 0.5x, 0.8x, 1.0x, 2.0x and 4.0x

- Quick-change bayonet lens mount for telecentric lenses

- Modular system work station

Case Study

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur. Excepteur sint occaecat cupidatat non proident, sunt in culpa qui officia deserunt mollit anim id est laborum.

John Doe – Vision Engineering