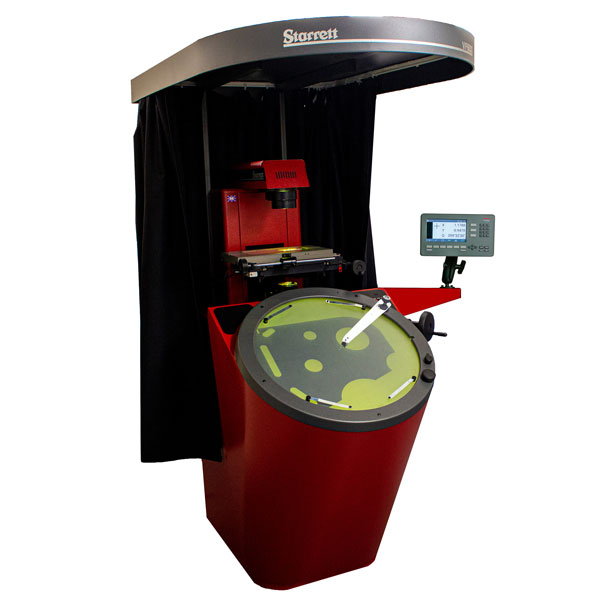

Starrett VF600 Vertical Floor Standing Shadowgraph

A vertical floor-standing shadowgraph

The Starrett VF600 is a robust floor-standing profile projector ideal for measuring large components and flexible or soft parts. With a market-leading specification, the VF600 has proved invaluable in the electronics, pressing and extrusions industries, among others. We also have a range of horizontal floor-standing models including the HF600, HF750, HS600 and HS750.

The large 600mm diameter screen of this shadowgraph is angled at 30° from horizontal for exceptionally clear and easy viewing and there is the option of a single lens mount or three lens turret for quick magnification changes. The workstage has a capacity of 30kg and a 200mm x 100mm X-Y axis measuring travel for greater inspection capabilities. Users of the VF600 have a choice of lenses from x5 to x100 magnification.

Renowned for their engineering expertise, the Starrett range of shadowgraphs is worth every ounce of investment.

A choice of software, the MetLogix™ or Quadra-Chek® geometric readout systems, screen overlay templates and automatic edge detection creating a complete metrology solution. Options include motorised XY travel and full CNC control.

Optimax engineers install and UKAS-calibrate all our measurement systems. These can also be upgraded to run with Optivu Synergy PC-based software. If you’re looking for a robust vertical floor standing profile projector, shadowgraph or optical comparator, the Starrett range offers an excellent solution. We also provide a range of Vision Systems

Specifications

- Available with MetLogix™ M1 tablet, M2 measuring software

- Screen is angled 30° from horizontal for clear, easy viewing

- Projection lens turret with three lens capacity (lenses not included)</li

- Single lens mount or 3-lens quick change turrett

- Linear encoder (glass scale) with 0.5μm resolution on both X and Y axes

- 600mm diameter screen

- 30kg capacity workstage

- Lenses available from x5 to x100

- Workstage with 400mm x 225mm top plate

- 200mm x 100mm measuring travel

Available with a large range of accessories, including:

-

The full range of Quadra-Chek readout systems

- Choice of five fixed magnification lenses

- Fully automatic CNC controls

- Motorized X-Y axis