Alicona IF-SensorR25

Optical 3D measurement sensor for production

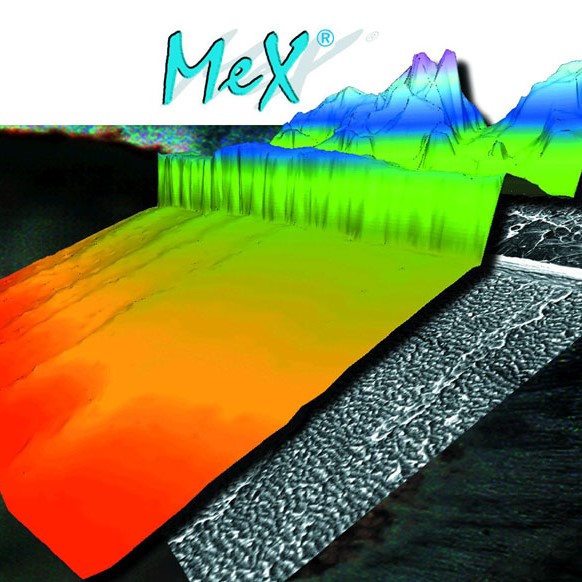

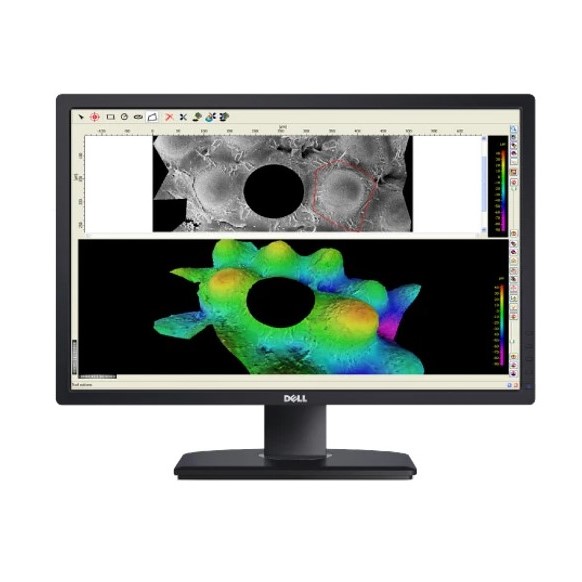

The Alicona R25 3D optical measurement sensor is based on the focus variation technique and is used integrated into a production environment to provide repeatable and traceable high-resolution 3D measurements in manufacturing conditions.

Operating in the μm or sub-μm range, and, using the same focus variation technique as the Alicona instruments in the measurement allows the same measurement process to be used in line allowing for easy comparison between the design and the manufactured products.

Standardised interfaces (e.g. QDAS) support an easy and quick integration into production allowing comparable measurements. In combination with a collaborative 6-axis robot, the SensorR25 is used as a collaborative system – Cobot System – for flexible quality assurance and the measurement of microstructures on large components.

Control and measurement can be fully automated, and after completion the worker can receive a measurement report indicating OK or not OK.